No.2612

Global Market of Colorless Polyimide Films for Foldable Smartphones: Key Research Findings 2020

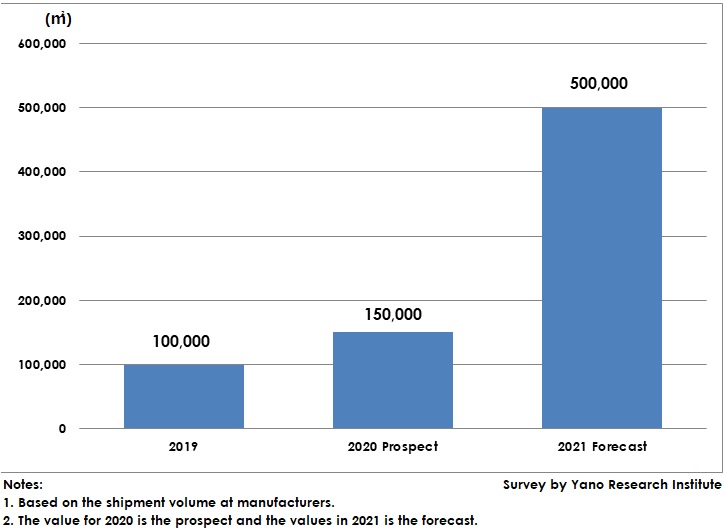

Global Shipment Volume of Colorless Polyimide Films for Foldable Smartphone Display Covers in 2020 Projected to Achieve 150,000 ㎡, 150% of Previous Year

Yano Research Institute (the President, Takashi Mizukoshi) carried out a survey on the global market of high-performance films for 2020 and found out the trends by product segment, the trends of market players, and the future outlook.

Disclosed here is the global shipment volume of colorless polyimide films for covering the display surface of foldable smartphones at manufacturers.

Market Overview

The perspectives of global high-performance film market in 2020 became unpredictable from the beginning of February just after the Lunar New Year to around May, due to the global COVID-19 pandemic. Some film manufacturers and converters saw the operation rate of their factories to have temporarily dropped to 20 to 30% in the first half of 2020, which prevented from formulating their full-year business planning. There had been some gloomy views that this sluggish demand for high-performance films would last for two or three years from 2020.

In fact, however, such demand shrinkage caused by the COVID-19 infections did not last long. China has started its economic activities in around April 2020, earlier than any other countries, followed by some other regions in around June the same year. The production activities of finished products including automobiles have actively resumed in the COVID-19 calamity, despite no sign of the infections to die down.

The promising high-performance films expected to expand the demand for the next few years even in this COVID-19 calamity are: Low-k (low dielectric constant) films used as components or secondary materials in the new markets such as 5G and autonomous driving; the films to cover the surface of foldable terminals; and highly-flat MLSS (Multi-Layered Ceramic Capacitor) release films.

Among such films, the global market size of colorless polyimide films for foldable smartphone display covers is expected to attain 150,000 m2 by 2020 based on the shipment volume at manufacturers, when considering throughput yield at the film processing and of built-in processes.

Noteworthy Topics

Global Colorless Polyimide Films Market Size Forecasted to Expand to 500,000 ㎡

The sales volume of foldable smartphones in 2020 is likely to soar to 6.5 times larger than the previous year. Nevertheless, the growth rate of film size against the sales volume of terminals remained low, because SEC (Samsung Electronics Co., Ltd.,) the manufacturer occupying 70% of the foldable phone market share, decided to shift the display cover materials from colorless polyimide film to ultra-thin glass. In addition, Razr, a folding smartphone manufactured by Motorola, has a small display size for a film to cover, and use only one piece of colorless polyimide film per phone.

Although SEC seems to continue using ultra-thin glass for the display cover for smartphones, other terminal manufacturers do not likely to shift to ultra-thin glass but to continue using films including colorless polyimide films, because ultra-thin glass has limited supply capacity and has a crack risk. The global market size of colorless polyimide films for foldable smartphone display covers in 2021 is forecasted to be 333.3% of the previous year to attain 500,000m2 based on the shipment volume at manufacturers.

Future Outlook

Some say that ultra-thin glass has succeeded in attaining both high surface hardness and flexibility, and that the films that have been replaced by the ultra-thin glass are no longer needed to cover the display surface of foldable smartphones. Nevertheless, ultra-thin glass has not eliminated the risk of cracking, though bendable to be adopted in the foldable phones. If the thin glass cracks in the course of manufacturing, tiny broken pieces may scatter. If such exceedingly small pieces of glass are scattered within a factory, the operation at that factory has to be stopped and the entire factory has to be removed of glass pieces from every corner. Therefore, the glass has a higher accidental breakage risk.

In addition, ultra-thin glass has surface hardness of 9H, but its extreme thinness causes the same problem as films, which is prone to even finger-nail scratches. Being highly hard, the glass cannot absorb an impact, which can lead OLED to easily break when a pen drops on the display surface and when a foreign substance is inserted at the time when the phone is folded. In order to prevent this, the surface of a terminal that use ultra-thin glass is laminated with shock-absorbing film, such as PET or urethane films, on top of ultra-thin glass. This indicates that the advantage of highly hard surface of the glass is not fully made use.

The current foldable phones can be folded in half, but some manufacturers are developing the phones to be trifold in the shape of “Z” or biparted from the center, in order to make the phones as compact as possible when folded and a larger screen when unfolded. Such forms of phones require further thinness for display surface. It may be difficult to adopt the current ultra-thin glass for such trifold or special formed phones when considering the performance as well as the limited supply capacity with only a few suppliers available for ultra-thin glass for foldable terminals.

Considering a problem of lower throughput yield at the time of lamination or incorporation of ultra-thin glass that has a breakage risk, which directly decreases profitability, it is hardly thinkable for all the foldable smartphone displays to be covered by ultra-thin glass. Rather, colorless polyimide films are likely to continue being adopted as the phone display covers for the time being.

Research Outline

2.Research Object: Film manufacturers and converters

3.Research Methogology: Face-to-face interviews by our expert researchers and literature research

What are High Performance Films?

High performance films in this research indicate base and process films used for displays & optical use, electric & electronic use, and for general industries. They include PET films, films for covering the display surface of foldable terminals (colorless polyimide films, optical highly colorless polyurethane sheets, and colorless aramid films,) low dielectric films (polyimide films, liquid crystal polymer films, PPS films,) MLCC (Multi-Layered Ceramic Capacitor) release films, etc.

<Products and Services in the Market>

PET films, colorless polyimide films, optical highly colorless polyurethane sheets, colorless aramid films, polyimide films, liquid crystal polymer films, PPS films, MLCC (Multi-Layered Ceramic Capacitor) release films,

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.