No.2094

Implementation Rate of Next Generation Monitoring System at Domestic Factories and Manufacturing Sector Reached 21.1% as of End of FY2017

Adoption Rate of Next Generation Monitoring in Factories of Japan: Key Research Findings 2018

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the next-generation monitoring systems and has found out the implementation rate by category, future outlook, and environmental changes regarding the shift from remote to IT monitoring, and trends of leading IT vendors and user companies.

Market Overview

Next-Generation Monitoring Systems are remote monitoring systems using IoT technologies. They collect the vast amount of big data or data at cloud services via sensor network or M2M, and analyze, determine, and evaluate them by using analytics and AI technologies. Remote systems have gradually changed their stages from data collection (data visualization) to utilization of data as more datacenters and cloud services are used, and as the network environment has become expanded.

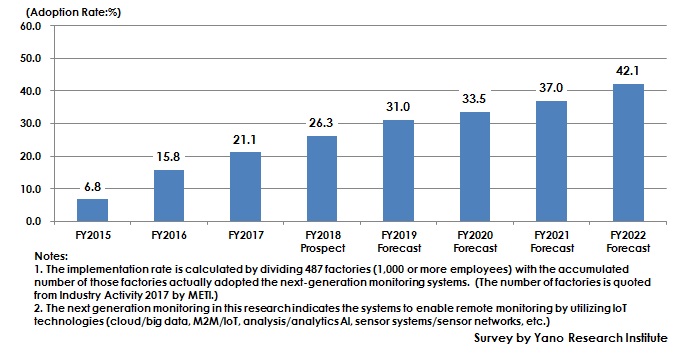

Adoption rate of next-generation monitoring systems in domestic factories and in the manufacturing sector as of end of FY2017 has been calculated as 21.1% (at 103 out of 487 factories with 1,000 or more of employees). It has become obvious that businesses tend to adopt next-generation-monitoring equipped manufacturing facilities at the time when the factories are newly constructed or upgraded. Therefore, the number of factories and facilities that implement next-generation monitoring is likely to increase further for the future, with the implementation rate as of the end of FY2022 to increase to 42.1% (205 factories).

In addition to conventional abilities of monitoring, which are visualization of monitoring operations and status, and also collection and recording of data, next-generation systems can enhance maintenance tasks (i.e., preventive maintenance and etc.), improve work efficiency (of product development, manufacturing, and maintenance), and reflect the improvement into product development and customer services. At advanced user companies in Europe and USA, verification of the systems such as Digital Twin and CPS (Cyber Physical Systems) has been in progress, in order to continuously monitor digitalized information on manufacturing processes onsite and products to be shipped. When looking at the transition from conventional to next-generation monitoring, the largest difference is how the data is treated. While conventional monitoring mainly aimed to merely collect data, next-generation monitoring aims to utilize the collected data.

Noteworthy Topics

The most promising users of remote monitoring or next-generation monitoring making use of IoT (i.e., IT monitoring) are factories and manufacturing sector, which have already used remote monitoring for machinery/equipment, production lines, boilers, air conditioners, pumps, and various other utility facilities. However, most of the data retrieved from such monitoring have only been used at the central monitoring room within the factories, and few have been utilized outside the factories or for cloud to be analyzed.

In 2010 and beyond, especially in the facility maintenance tasks, IT monitoring has been increasingly used, especially for those projects initiated by industrial machinery makers. Maintenance jobs are indispensable to improve productivity, availability rate, and safety. On the other hand, however, there are needs to reduce costs. IT monitoring is expected as a method to satisfy the both demands.

Research Outline

2.Research Object: IT vendors, user companies/organizations (various manufacturers, constructors, transporters, warehousing companies, service providers, and local governments/public bodies, etc.)

3.Research Methogology: Face-to-face interviews by our expert researchers, surveys via telephone, partly face-to-face interviews by the specialized researchers and literature search.

The next generation monitoring in this research indicates the systems to enable remote monitoring by utilizing IoT technologies (cloud/big data, M2M/IoT, analysis/analytics AI, sensor systems/sensor networks, etc.) They largely differ from the conventional remote monitoring systems in that they place importance on generating added values to the data collection and analysis of the collected data.

This research targets services and solutions that are sold by IT vendors. However, those in-house systems (on premise) developed by user companies and organizations, and those maintenance/support services provided by various manufacturers of industrial devices and equipment are excluded. Those services and solutions that are sold by IT vendors include: MMCloud, Facteye, Industrial IoT, DoctorCloud, Facility Monitoring Service, and etc.

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.