No.3975

Global Recycled Carbon Fiber Market: Key Research Findings 2025

Recycled Carbon Fiber Industry in Next Phase: Toward Stronger Focus on Application

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the global market of recycled carbon fiber (rCF) and found out the trends of market players and future perspective. This press release denotes the forecast on the global volume of recycled carbon fiber.

Market Overview

Carbon fiber-reinforced plastic (CFRP), a composite material consisting of carbon fiber and plastic, is used across a wide range of applications, including aircraft components, wind turbine blades, pressure vessels, automobiles, and sports and leisure goods. The global CFRP market size in 2024 is estimated at 168,800 tons, of which approximately 14% (23,600 tons) is generated as prepreg waste and manufacturing offcuts. When this volume is combined with the estimated amount of CFRP products reaching end-of-life in 2024, total CFRP waste generation is evaluated at 64,070 tons. This volume is expected to increase in line with the expansion of the CFRP market.

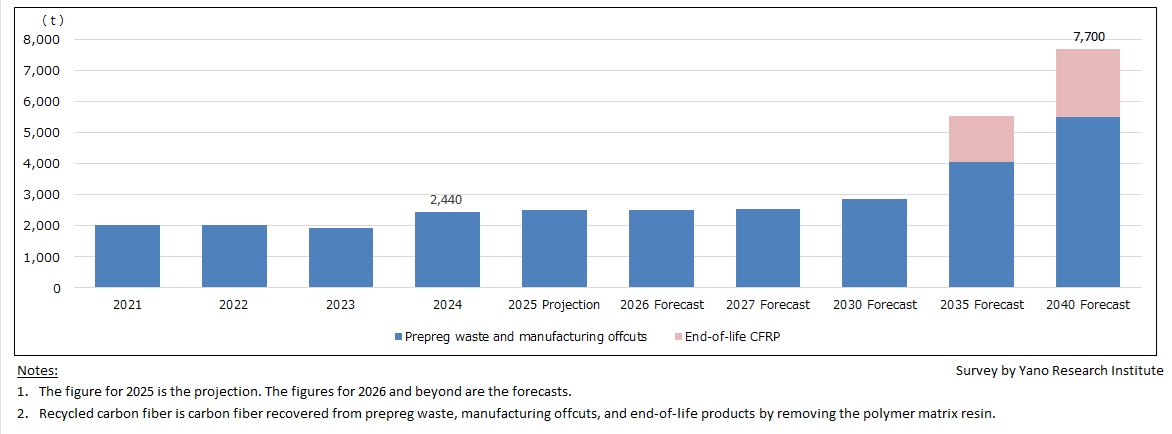

In 2024, however, no more than 7% of the CFRP waste was collected for recycling. Consequently, the volume of recycled carbon fiber (rCF) recovered from collected CFRP waste—through the removal of the matrix resin—amounted to only 2,440 tons, equivalent to slightly more than 2% of the pan-based virgin carbon fiber (vCF) produced in the same year. Although the volume of recovered carbon fiber is expected to increase as the CFRP market expands, the projected production volume of rCF is estimated to reach only 7,700 tons by 2040.

Despite ongoing technological advances in CFRP recycling, the utilization of recycled carbon fiber in fabrication remains limited. This is largely due to difference in fiber form: virgin carbon fiber is supplied as continuous fibers, whereas recycled carbon fiber consists of discontinuous fibers. As a result, molding methods developed for vCF are generally unsuitable for rCF, and fabrication manufacturers have yet to establish sufficient expertise in rCF processing. In addition, CFRP recyclers—whose primary focus is the recovery of carbon fiber from CFRP—tend to prioritize the extraction of high-quality fibers, with limited consideration of downstream applications. To promote wider adoption of rCF, recyclers will need to adopt a broader perspective in their technological development efforts.

Noteworthy Topics

Recyclers to Material Manufacturers: Elevating the Value of rCF Beyond vCF

As long as recycled carbon fiber is positioned merely a recycled substitute with properties comparable to those of virgin carbon fiber (vCF), its scope for application will remain constrained. Because rCF cannot be processed using molding techniques designed for vCF, fabrication manufacturers have little incentives to incur the additional cost and effort required to transition to rCF-based manufacturing. To accelerate adoption and expand end-use applications, rCF must offer added value beyond environmental benefits and parity in basic performance, and this value must be clearly communicated and recognized by fabrication manufacturers.

Although the adoption of recycled materials—including rCF—is being promoted across a wide range of industries as part of national sustainability initiatives aimed at reducing greenhouse gas emissions, sustainability alone is insufficient to drive user adoption. To unlock broader market acceptance, recyclers must move beyond their traditional role and evolve into material manufacturers. This entails developing, producing, and actively proposing rCF materials that deliver superior functionality, processability, or cost-performance compared with vCF.

Future Outlook

Japanese carbon fiber recyclers have traditionally focused on developing and supplying recycled carbon fiber (rCF) with properties comparable to those of virgin carbon fiber (vCF). However, fabrication manufacturers do not necessarily base their material selection solely on intrinsic performance or quality. From the user perspective, materials must also offer additional functionality, ease of handling, and potential for cost reduction. Without clear and tangible advantages, manufacturers have limited incentive to shift from established vCF-based processes to rCF.

Accordingly, simply positioning rCF as a "high-quality" alternative is insufficient to drive adoption unless end users are convinced of its practical benefits. To address this gap, recyclers need to reorient their technological development efforts from a primary emphasis on fiber recovery toward a stronger focus on application development, including the creation of end-use solutions that leverage the specific characteristics of rCF. Such a transition would contribute not only to the expansion of the rCF market but also to the broader development of the carbon fiber and composite materials market. Given Japan’s established strengths in carbon fiber and composite material technologies, this shift could further reinforce its position in the global market.

Research Outline

2.Research Object: Carbon fiber manufacturers, carbon fiber recyclers, fabrication manufacturers of recycled carbon fiber, research institutions

3.Research Methogology: Face-to-face interviews by our expert researchers (including online interviews) and literature research

What is the Recycled Carbon Fiber?

In this research, recycled carbon fiber refers to carbon fibers recovered from prepreg waste, manufacturing offcuts, and end-of-life products made of carbon fiber–reinforced plastics (CFRP) through the removal of the matrix resin.

<Products and Services in the Market>

recycled carbon fiber (rCF), virgin carbon fiber (vCF), carbon fiber reinforced plastic (CFRP)

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.