No.3921

Global CMP Slurries Market: Key Research Findings 2025

Global CMP Slurry Market Show 10% Growth in 2024

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the global CMP slurry market and found out the market trends by product segment and future perspectives.

Market Overview

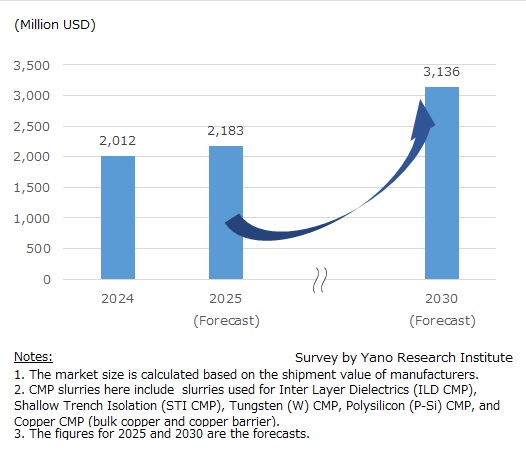

CMP slurry is a chemical solution containing nano-sized abrasive particles used in Chemical Mechanical Polishing (CMP), a process that planarizes the surface of semiconductor wafers. Because it is directly tied to semiconductor production, trends in the CMP slurry market generally move in line with those of the overall semiconductor industry. Driven by rising demand for semiconductors used in generative AI and data centers, the global CMP slurry market in 2024 grew to US$201.2 billion, up 10.1% from the preceding year.In the latter half of 2024, the CMP slurry market was supported by solid growth in memory segments such as DRAM and NAND. Shipment volumes increased in response to strong demand from leading Taiwanese semiconductor foundries, which have been rapidly expanding production, as well as from Chinese IDMs and foundries. Against this backdrop, the global CMP slurry market recorded double-digit growth.By application, CMP slurries can be broadly categorized into those used for oxide layer polishing—including Inter Layer Dielectric (ILD) CMP, Ceria (cerium oxide)-based slurry, and polysilicon (P-Si) CMP—and those used for metal-layer polishing, such as Tungsten (W) CMP, Copper Bulk CMP, and Copper Barrier CMP. In 2024, the market size for oxide-related slurries reached US$898 million, while metal-related slurries totaled US$111.4 million.

Noteworthy Topics

Copper CMP Slurries Maintain Solid Growth in Advanced Logic Semiconductor Applications

Among slurries for metal-layer polishing, Tungsten (W) CMP slurries continue to see growth in advanced logic applications, such as FinFET (a type of transistors with a three-dimensional channel structure that are surrounded by gates on three sides) and GAAs (Gate All Around), an advanced transistor design where the gate fully wraps around the semiconductor channel. Meanwhile, driven by the increasing number of layers in advanced logic devices, demand for Copper Bulk CMP and Copper Barrier CMP is rising sharply and is expected to maintain solid growth in the coming years.

In 2024, slurry suppliers serving leading Taiwanese foundries benefited from this surge in shipments. The expansion is expected to continue in 2025 and beyond, as major Taiwanese foundries plan to gradually increase the number of copper layers on semiconductor from 16 to 23. In addition, new materials such as cobalt (Co), ruthenium (Ru), and molybdenum (Mo) are beginning to emerge in the CMP slurry market.

Future Outlook

The global CMP slurry market size is projected to reach US$2,183 million in 2025, representing 108.5% of the preceding year’s value (based on the shipment value of manufacturers). Demand for CMP slurries is showing robust growth, driven by the expansion of foundries in advanced chip manufacturing due to strong demand for semiconductors in generative AI and data centers, as well as rising demand for memory applications such as high-bandwidth memory (HBM).

While the growth rate in 2025 may be slightly slower than the 10% annual increase seen in 2024, demand for CMP continues to rise, fueled by the adoption of hybrid bonding technology—which involves separating logic and memory into distinct dies that are subsequently assemble—and advancements in fine processing technologies. Together, these factors underpin ongoing growth in the CMP slurry market.

Research Outline

2.Research Object: CMP slurry manufacturers and related manufacturers

3.Research Methogology: Face-to-face interviews by our expert researchers (including online interviews) and literature research

CMP Slurry Market

Chemical Mechanical Polishing (CMP) slurries are chemically reactive solutions containing nano-sized abrasive particles used to planarize microchip wafers, creating an extremely flat surface. A typical slurry consists of an aqueous base such as water, polishing particles like silica or alumina, and surface-modifying chemical additives. Together, these components enable the nanoscale flatness for advanced, highly integrated circuits.

In this context, CMP slurries include those used for Inter Layer Dielectric (ILD) CMP), Shallow Trench Isolation (STI) CMP), Tungsten(W) CMP, polysilicon (P-Si) CMP, and Copper CMP. The global CMP slurry market is calculated based on the shipment value of slurry manufacturers.

<Products and Services in the Market>

CMP slurries

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.