No.3679

Perovskite Solar Cell/Components Market in Japan: Key Research Findings 2024

Demonstrations, Test Marketing, and Capital Investment for Mass Production Underway to Commercialize Perovskite Solar Cells

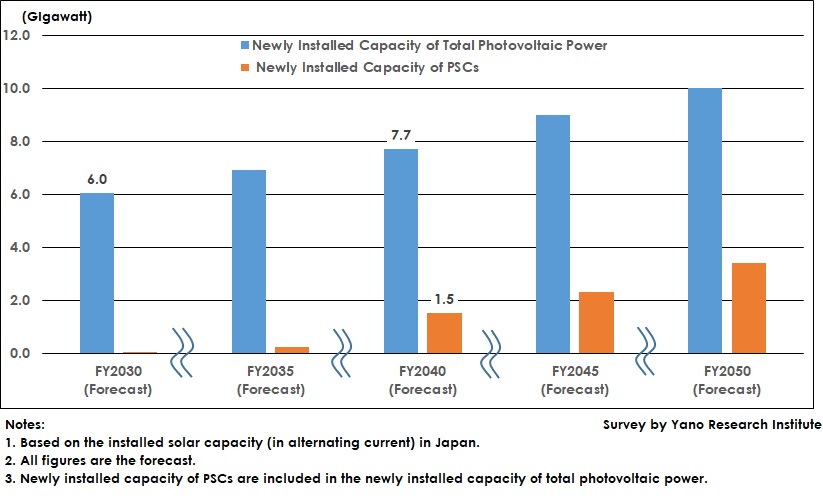

Yano Research Institute (the President, Takashi Mizukoshi) has studied the domestic market of perovskite solar cells and their components and found out the trend of market players and future prospects. The forecast of newly installed capacity of photovoltaic power as well as of perovskite solar cells is highlighted here.

Market Overview

A perovskite solar cell (PSC) is considered as a promising next-generation solar cell due to its lower environmental impact than existing crystalline silicon solar cells in manufacturing, domestic sourcing availability of components and materials, light weight, and high efficiency. In the “Public-Private Consortium for Increasing the Installation of Next-Generation Solar Cells and Strengthening Industrial Competitiveness” led by the Agency for Natural Resources and Energy, the policy to “consider the prerequisite of building GW-class mass production system before 2030” has been formed to expand the installation of PSCs.

On the other hand, mass production by PSC manufacturers is not expected until around 2028 or 2029 at the earliest, making it difficult for the country to secure GW-class power generation capacity at this stage. As PSCs are likely to be installed initially on a trial basis in public facilities or public residences, the share of newly installed capacity of PSCs in total new PV power capacity is forecast to start at around 1%. Later, PSC applications in vertical areas such as the walls of roofs or the exterior of buildings with weight restrictions such as factories and warehouses are expected to increase. By FY2024, the newly installed capacity of PSCs is projected to reach 1.5GW, accounting for 19.5% of the newly installed capacity of total PV power.

People may think that this projected figure is too conservative when the government aims to build a GW-class mass production system by 2030. However, replacing existing solar cells with PSCs to secure capacity will not be profitable, because it will cause price competition with crystalline silicon solar cells or PSCs produced overseas. If Japan wants to promote PSCs as a high value-added industry, it should explore applications and markets that only PSCs can contribute to, rather than existing crystalline silicon solar cells, instead of pursuing scale-oriented policies such as building a GW-scale production.

* “Solar Power Market in Japan: Key Research Findings 2024” (09/06/2024)

https://www.yanoresearch.com/en/press-release/show/press_id/3613

Noteworthy Topics

Japan’s Original High Value-Added Development

In the conventional solar power generation business, companies have been able to generate revenue by selling electricity produced at their large-scale (mega-solar) plants to electricity companies. However, with solar panels already installed in most of flat lands in Japan, new land for installations has become limited. What is needed hereafter is to generate electricity for onsite consumption (local production and local consumption of electricity) at buildings or commercial facilities by installing solar panels in small spaces in urban areas. This is where the lightweight and flexible film-based PSCs developed by Japanese companies (solar cell and material manufacturers) come into their own.

Film-based PSCs use the so-called roll-to-roll manufacturing method of depositing the power-generating layer and the charge transfer layer on the substrate or base material and is what Japanese manufacturers are good at. Since a film-based PSC is formed by coating the perovskite, charge transfer, and other layers on the base material, the technique used to control these deposition processes of coating and drying determines the quality of the PSC and the device features. The proportion of perovskite precursor solution, the combination of coating liquid, base material, and deposition facility, and the optimization of drying conditions, are what Japanese manufacturers have been striving for in their film converting techniques.

If the market for flexible and high-value-added PSCs that do not end up simply replacing crystalline silicon solar cells can be created through experienced film conversion techniques, they can secure unique demand that can avoid competition with future low-cost PSCs from overseas.

In the case of glass-based PSCs, a Japanese manufacturer has combined glass material with PSC to develop a glass construction material that is equipped with power generation functions but has the glass properties of transparency and glass design. By producing a small number of different types, according to demand, Japanese manufacturers may be able to develop high value-added products that are differentiated from overseas products.

Future Outlook

Unlike mega solar parks that use crystalline silicon solar cells, to ensure installed capacity in the limited space in urban areas, it is necessary to use PSCs that can be installed on the vertical wall of a building in as many places as possible. If the government is serious about securing a GW-class installed capacity, it must first take measures to install PSCs in public facilities as a model case, such as in a government office building, schools, disaster prevention facilities, public residences, etc. It should be effective to provide stimulative support such as subsidies to local governments that are proactive in PSC installations.

It may be possible to create a virtuous cycle of alliance between PSC manufacturers and the government or the municipality to accumulate installations, which may lead to the reduction in manufacturing costs due to economies of scale from expanded installations, which may lead to greater adoption of PSCs in private facilities. If more PSC installations are expected, PSC component manufacturers may expand production capacity through additional capital investment and new technological development, which may lead to technological breakthroughs. Finally, the cost of PSC components is expected to decrease, further removing the bottleneck for PSC diffusion.

To realize this scenario, the efforts are needed to explore the demand and applications for PSCs through cooperation among the government, municipalities, and companies, in addition to the support from the Green Innovation Fund led by the New Energy and Industrial Technology Development Organization (NEDO) for technological development of PSCs.

Research Outline

2.Research Object: Perovskite solar cell manufacturers, component manufacturers, R&D institutions including universities, etc.

3.Research Methogology: Face-to-face interviews (including online) by expert researchers, and literature search.

What is Perovskite Solar Cell and Its Components?

A perovskite solar cell (PSC) is a type of solar cell that has a perovskite crystal structure in its power-generating layer. It is considered as a promising next-generation solar cell due to its lower environmental impact than existing crystalline silicon solar cells in manufacturing, domestic sourcing availability of components and materials, light weight, and high efficiency.

PSCs can be classified into film-based, glass-based, and tandem (combination of perovskite and silicon-based cells), based on the material used. This research has been conducted mainly on film-based and glass-based cells, as demonstrations for these cells are underway in Japan.

Perovskite solar cell components in this research refer to transparent electrode film, barrier film, and cover film, which are used as the base material or the barrier layer for film-based PSCs.

<Products and Services in the Market>

Perovskite solar cell (PSC), perovskite solar cell components (transparent electrode film, barrier film, and cover film)

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.