No.2394

Global Nondestructive Inspection Instrument Market for “Monozukuri” or Manufacturing: Key Research Findings 2019

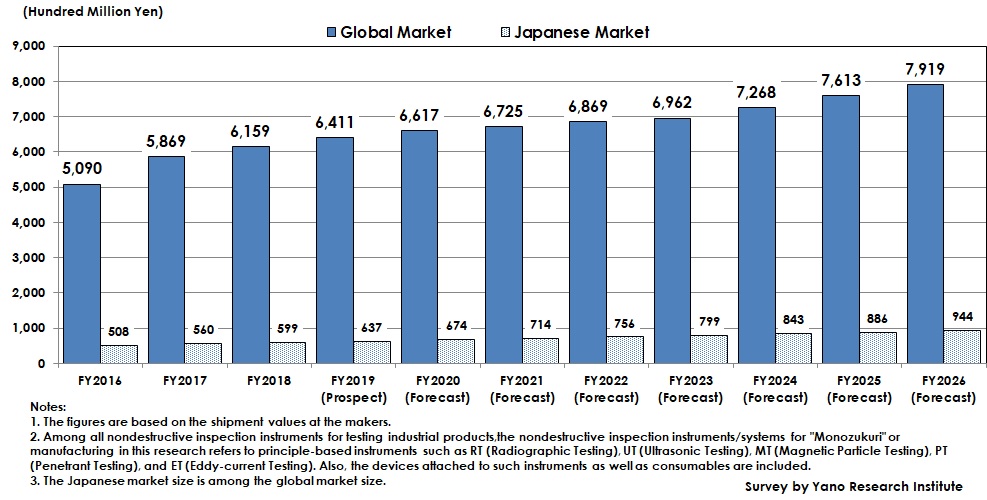

Global Nondestructive Inspection Instrument Market for “Monozukuri” in FY2019 Expected to Rise by 4.1% to Reach 641,100 Million Yen, among which Japanese Market to Attain 63,700 Million Yen

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the global nondestructive inspection instrument market for “monozukuri” or manufacturing, and has found out the trend by industry, by inspection type, and future outlook.

Market Overview

The market size of nondestructive inspection instruments/systems for "Monozukuri" or manufacturing based on the shipment values at the makers for FY2019 achieved 641,100 million yen, 104.1% of that of previous fiscal year. When observing it by inspection type, RT (Radiographic Testing) reached 281,400 million yen, occupying the largest market share of 43.9%, followed by UT (Ultrasonic Testing) accounting for 21.6%, 138,500 million yen, meaning that more than 20 points difference in the market share between the top two. They are followed by MT (Magnetic Particle Testing) attaining 62,800 million yen, PT (Penetrant Testing) 44,900 million yen, and ET (Eddy-current Testing) 39,100 million yen, each accounting for 10 to 6 % of the market.

The importance of nondestructive inspection instruments for “monozukuri” is not to interrupt the processes of entire manufacturing plan. A nondestructive inspection instrument is introduced in the plant only after meeting the strict standards and solving all the concerns, not only limited to speed and quality but also the size, radiation, and other factors.

Because the facilities at manufacturers are nothing but those for manufacturing products, inspection tends to be regarded as low in priority. In addition, since tact time (time period to manufacture a product) is important, it is indispensable for each manufacturing process to have balanced progress throughout the production procedure. Therefore, an inspection instrument must not be the obstacle of mass production.

For nondestructive inspection instrument makers, the following are the positive factors for their product to be introduced at manufacturers:

1. Technological progress in inspection instruments:

-Advancement of new software/system that was not available before.

-Being able to meet the needs at manufacturing site, i.e., fast, accurate, and low-price inspection, instead of previous inspection that used to be slow, inaccurate, or too costly for a function.

-Improved processing speed of computers, leading to faster speed at manufacturing site.

-Improved image resolution by contriving materials and structure.

-Volume discount available for materials and devices of inspection instruments (including those used for other purposes) due to wider acceptance of the instruments.

-Improved cost effectiveness due to decreased prices.

2. Changes of Recognition in Organizations and at Manufacturing Sites

-Changes in applications and stricter quality levels required by customers.

-Improved reliability in inspection records by compliance.

-Shift of resources from personnel expenses to fixed cost (equipment cost).

-Introduction of machines needed due to manpower shortage.

-Introduction of machines needed due to lifestyle reform.

3. Regulations

-Introduction affected by social issues.

Noteworthy Topics

Keys for Market Revitalization in AI and IoT, Higher Demand for Total Inspection

In recent years, inspection processes are supported by the computers, and AI has been used extensively. In order to use AI for judging the inspection results, acquiring image data for such results is essential. Therefore, the AI-used judgement is likely to be applied increasingly to such data. When observing the non-destructive inspections by principle, judgement by AI is difficult for RT, preventing the progress of AI-used judgement for RT, which indicates that the judgement of Xray image by humans is also as much difficult. Since management of image data can hardly be achieved in MT, PT, and ET, AI-used judgement cannot be applied to such inspections, either.

Non-destructive inspections differ from destructive inspections in that they maintain the product value. Inspections occur in various timing throughout the entire production processes: At when accepting raw materials, at the interval between the two manufacturing processes, just before shipment to customers in order to secure the product quality, etc. Inspections for products are not limited to total inspections, but are also done by lot, or at the timing of a certain time passed, or blind check done at random. They are conducted differently by product or quality standard.

Nevertheless, non-destructive inspections cannot change a defective product into a flawless product. Therefore, the goal for the plant that found a defective product by inspection is to increase the ratio of flawless products as much as possible in the manufacturing processes prior to the inspection. Although some blind checks are conducted, the demand for total inspections is on the rise as a general tendency.

Some manufacturing processes do not have inspection standards, but it cannot be said as bad as a rule. Because many of the non-destructive inspection principles are limited to those used from the past, almost without new methods, and because some time had been passed since launch of the existing standards, despite new materials have begun used in some of manufacturing processes, unchanged standards can sometimes lead to excessive quality. It is true that there are some cases where the materials including new ones are underdeveloped or the product quality cannot be kept uniform, but there are some inspections done forced by the standards though actually not necessary anymore (especially for infrastructure).

In order to breakthrough such a situation, updating or easing of standards can be considered. However, it is difficult for the standard of inspections for absolute safety to be eased. Even if it were eased, changes in the development or the market conditions may have to urgently update the standard to be stricter again. Therefore, the industrial organizations are required to find a good timing to update the current standard, after sufficient discussions.

Future Outlook

The global non-destructive inspection instrument market size (based on shipment values at the makers) is projected to reach 791,900 million yen by FY2026. The inspections for automobiles are likely to keep large market share by industry, and RT instruments continue to be the most popularly introduced.

Hereafter, use of machinery or new technologies like IoT and AI is likely to be in progress in manufacturing. Non-destructive inspection instruments for manufacturing, therefore, are required not simply for judging any inferior products but potentially for more important roles in quality management. In addition, the development of instruments is focused on user-friendliness, so that the instruments may improve significantly in terms of usability, not to mention performance.

Research Outline

2.Research Object: Makers of nondestructive inspection instruments and systems for “monozukuri,” trading houses, related auxiliary organizations and R&D institutions

3.Research Methogology: Face-to-face interviews by the specialized researchers and literature research

Nondestructive Inspection Instruments/Systems Market for "Monozukuri" or Manufacturing

Among all nondestructive inspection instrument for inspecting industrial products, the nondestructive inspection instruments/systems for "Monozukuri" or manufacturing in this research refers to principle-based instruments such as RT (Radiographic Testing), UT (Ultrasonic Testing), MT (Magnetic Particle Testing), PT (Penetrant Testing), and ET (Eddy-current Testing), therefore, cameras and other equipment that test or inspect using visible light are not included.

The instruments in this research carry out the inspections at the time of “monozukuri”, i.e., manufacturing, so that those devices in a laboratory for analysis are not included. Also, nondestructive inspection instruments for medicines and food used at the time of manufacturing are excluded from this research.

In the market size, not only the inspection instruments and systems but also the devices attached to such instruments as well as consumables are included.

<Products and Services in the Market>

nondestructive inspection instruments used for industrial products at the time of the products are manufactured

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.