No.3794

The Factory Digitalization Market in Japan: Key Research Findings 2025

Japanese Manufacturing Showed Robust Digitalization Investments for Transportation Machinery and Equipment (Mainly for Automobiles), Electronic Parts, Devices, and Electronic Circuits

Yano Research Institute (president, Takashi Mizukoshi) conducted a survey on the domestic factory digitalization market. The survey discloses trends in the use of technologies such as IoT and AI in manufacturing sites, as well as the implementation of smart factories/digital factories, digital twins (DT), and cyber-physical systems (CPS). In here highlights the forecast of the size of the domestic factory digitalization market.

Market Overview

In factories for many industries in Japan, IoT, cloud, and AI technologies are used for data collection and analysis, monitoring and maintenance management of production facilities and equipment, product appearance inspection, and locational information management of materials and transportation equipment, among other purposes. These implementations contribute to abnormality detection, fault surveillance, visualization of energy savings or consumption, next-generation quality assurance, advanced automation, and advanced work support for on-site workers.

This began with the initial embedding of telecommunications abilities (IoT features) in manufacturing equipment, production machinery, automated transport equipment, and products themselves since the latter half of the 2010s, which has gradually evolved into a system that collects and accumulates operational, image, locational, and various sensor data.

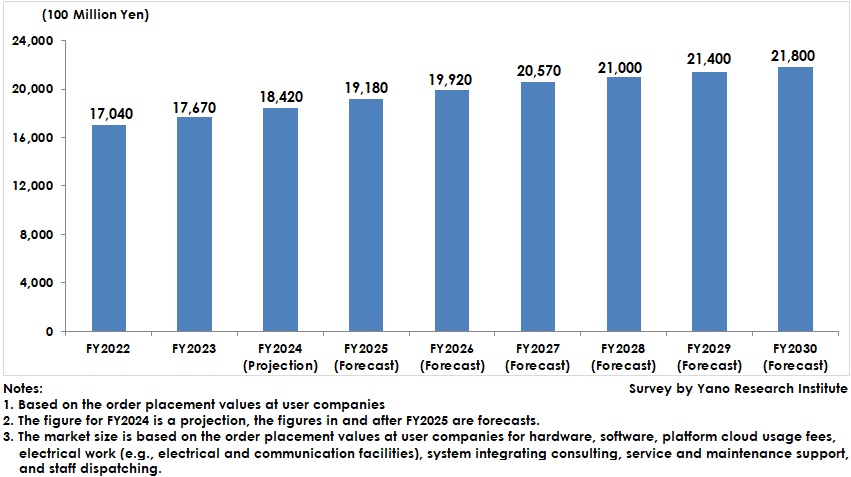

In FY2023, the market size for factory digitalization in Japan was estimated at 1,767.0 billion yen, 103.7% of the size of the previous fiscal year, based on the order values placed by user companies. This growth owed to the market's tailwind, as IT investments in factories resumed as planned after being suspended due to the pandemic.

Noteworthy Topics

Shift of Manufacturing to Provide Services

Manufacturing business models are changing as sales of standalone products, which used to be the mainstream sales, have decreased. Packaged service models, (e.g., pay-as-you-go, subscriptions, value sharing, and post-business models) have become more common. These models include post-sales and maintenance support, and the provision of consumables in addition to product sales.

Multifunctional peripherals (MFPs), which are charged by the counter, are one example of these models. They have already been adopted in production and utility facilities, as well as in industrial robots. Some compressor manufacturers offer pay-as-you-go models that charge based on the volume of compressed air.

Future Outlook

FY2024 shows the market to be overall favorable, because of robust digitalization investments in transportation equipment manufacturing, centered on automobiles; the establishment of new semiconductor factories; reinforced semiconductor production capabilities; and the return of domestic manufacturing due to external environmental changes, such as a stabilized weaker yen, economic security, and managing China risks. However, the so-called “Trump risk” has become the concern since the second half of FY2024, prompting some companies to reconsider or delay their investment plans.

Nevertheless, the factory digitalization market is projected to reach 1,842.0 billion yen in FY2024, up 4.2% year over year, due to increased digitalization of manufacturing sites overall.

Research Outline

2.Research Object: IT vendors, system integrators, equipment manufacturers, telecommunications careers, equipment manufacturers’ IT subsidiaries, application vendors, etc.

3.Research Methogology: Face-to-face interviews (including online) by expert researchers, survey via telephone and questionnaire, and literature research

The Factory Digitalization Market

Factory digitalization refers to IT investments for manufacturing sites, including technology applications such as the Internet of Things (IoT), cloud technology, and artificial intelligence (AI), and data platform construction (i.e., smart factories or digital factories), aiming at work efficiency and automation, cost reduction, and onsite visualization.

The size of the factory digitalization market in this research has been calculated based on the order placement values at user companies for hardware, software, platform cloud usage fees, electrical work (e.g., electrical and communication facilities), system integrating consulting, service and maintenance support, and staff dispatching.

In other words, these values represent cash outflows at user companies and can be contrasted with IT sales at IT vendors, system integrators, equipment manufacturers and their IT subsidiaries, and telecommunications companies. Note that in-house equipment for user companies is not included.

<Products and Services in the Market>

Process management, operation monitoring, remote monitoring, energy management (energy saving), quality management, appearance inspection, product inspection, maintenance, work support for on-site workers, supply chain management, asset management, etc.

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.