No.3932

Global High-Performance Separation Membrane Market: Key Research Findings 2025

Global High-Performance Separation Membrane Market Forecasted to Hit 190 Billion Yen-Level by 2032

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the global high-performance separation membrane market (CO2 separation membrane and hydrogen separation membrane), and found out the trends by product segment, market player trends, and future perspectives.

Market Overview

Membrane separation technology is applied across a wide range of fields, including water treatment, food, pharmaceuticals, chemicals, petroleum, and steel. In recent years, research and development have particularly accelerated in hydrogen separation membranes, which are used for the separation and purification of hydrogen, and CO2 separation membranes, which contribute to improving the economics of carbon recycling and CCS/CCU. In this survey, we have positioned these two types of membranes as high-performance separation membrane.

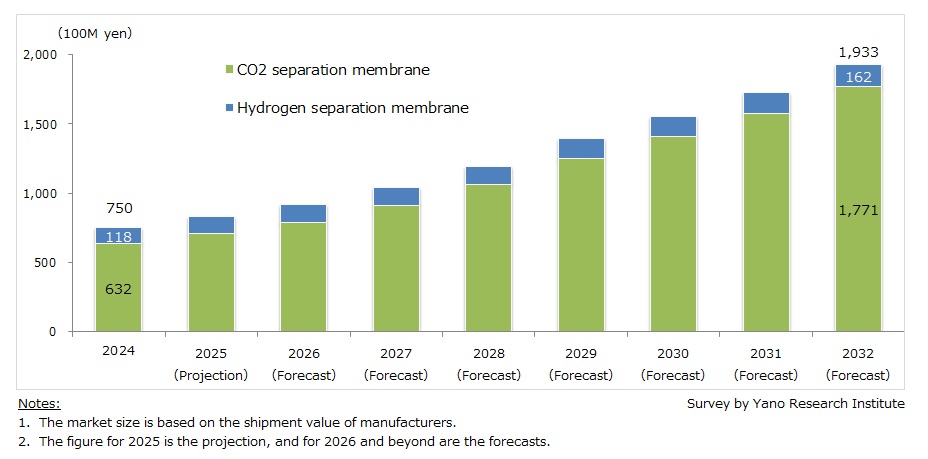

The size of global High-performance Separation Membrane market in 2024 is estimated at 75 billion yen (based on the shipment value of manufacturers), with CO2 separation membranes market and hydrogen separation membranes market yielding 63.2 billion yen and 11.8 billion yen, respectively.

Noteworthy Topics

CO2 Separation Membranes Global Trends

CO₂ separation membranes can be broadly categorized by gas type: (1) process gases, from which CO₂ is captured during industrial processes, and (2) flue gases, from which CO₂ is captured primarily for environmental purposes. The former category includes natural gas, biogas, associated gas (natural gas found with crude oil in oil reservoirs), and the latter refers to the mixture of gases generated from fuel combustion in facilities such as coal-fired power plants, petrochemical plants, cement plants, and steel mills.

Another way to classify CO2 separation membrane is by the scale of CO2 emissions, distinguishing between small-to-medium-scale facilities (such as small and medium-sized factories, biogas plants, and garbage incineration plants) and large-scale facilities (such as natural gas fields, coal-fired power plants, and petrochemical plants). CO2 separation membrane technology is particularly well suited to facilities with relatively low energy consumption, as it offers advantages such as compact equipment size and a simplified process.

In recent years, demand for separation membrane has been growing in the field of biogas purification. Biogas is an energy source produced through the methanogenesis (anaerobic digestion) of organic matter such as food scraps and livestock manure, as well as from combustible gases produced by the thermal decomposition of organic materials. It typically consists of approximately 60% methane (CH4) and 40% carbon dioxide (CO2), with trace amounts of nitrogen (N), oxygen (O), hydrogen sulfide (H2S), and water vapor (H2O). The use of biogas for electricity and heat generation is regarded as a form of renewable energy, since the CO2 emitted from its combustion is considered “plant-derived carbon”—originating from the natural cycle.

While the utilization of biogas has a long history, it has increasingly gained attention as an energy source contributing to achieving carbon-neutrality, given its ability to address both waste management and energy production simultaneously. Its prominence has grown further as instability in the fossil fuel energy market intensified following Russia's invasion of Ukraine.

Traditionally, there was little incentive to produce biomethane through costly purification processes, since biogas could be used directly for power generation or as a fuel gas. However, the value of biomethane is now being recognized, as it can be used without significant modifications to existing natural gas infrastructure.

Amid these developments, investment in biogas purification facilities has accelerated. According to the IEA, the global supply of biomethane reached approximately 10 billion cubic meters in 2023*. Although chemical and physical absorption methods are also used for biogas purification, membrane separation is increasingly adopted as a more energy-efficient alternative.

*Souce: World Energy Outlook 2024, IEA [https://iea.blob.core.windows.net/assets/140a0470-5b90-4922-a0e9-838b3ac6918c/WorldEnergyOutlook2024.pdf], License: [CC BY 4.0]

Future Outlook

Going forward, biogas purification will be driving the demand growth of CO2 separation membrane, while the demand for hydrogen separation membrane will show robust growth in petrochemical sector. By 2032, the global markets for CO2 separation membrane and hydrogen separation membrane are forecasted to grow to 177.1 billion yen and 16.2 billion yen, respectively.

The size of the global high-performance separation membrane market as a total of the two separation membranes will grow at CAGR of 12.6% between 2024 and 2032, reaching 193.3 billion yen.

Research Outline

2.Research Object: Enterprises in business pertaining to CO2 separation membrane and/or hydrogen separation membrane, universities and research institutions

3.Research Methogology: Face-to-face interviews by our expert researchers (including online interviews) and literature research

What is the High-performance Separation Membrane Market?

In this research, the high-performance separation membrane market includes carbon dioxide separation membrane and hydrogen separation membrane, and the market size is calculated based on the shipment value of manufacturers.

A CO₂ separation membrane selectively permeates carbon dioxide by exploiting differences in molecular size, solubility in the membrane material, and diffusion rates among mixed gases. Similarly, a hydrogen separation membrane selectively allows only hydrogen to permeate from gas mixtures containing hydrogen.

<Products and Services in the Market>

Carbon dioxide separation membrane (for purification of natural gas and biogas, emission gas recovery, etc.), hydrogen separation membrane (in petrochemical and semiconductor segment)

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.