No.3793

PET Bottle Recycling Market in Japan: Key Research Findings 2024

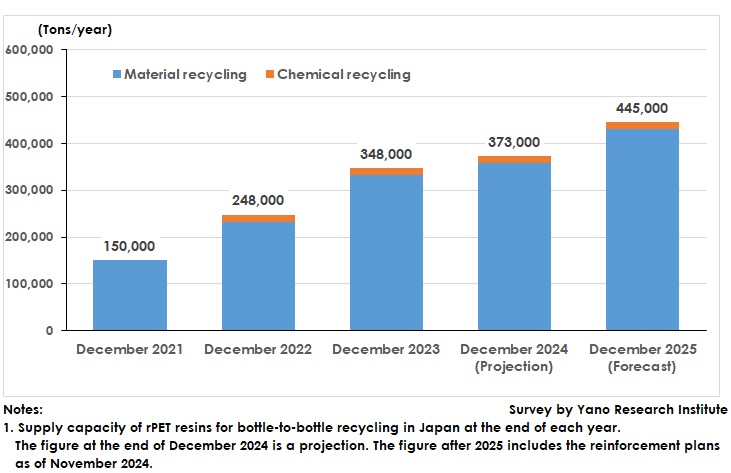

Supply Capacity of Recycled PET (rPET) for Bottle-to-Bottle Recycling in Japan Estimated at 373,000 Tons as of End of December 2024

Yano Research Institute (the President, Takashi Mizukoshi) surveyed the trend of domestic eco-friendly material manufacturers in Japan. The survey covered trends by product segment, market player trends, and market outlook.

The following are perspectives on the supply capacity of recycled PET (rPET) for bottle-to-bottle recycling in Japan.

Market Overview

Major soft drink brand owners (beverage manufacturers) are promoting environmentally friendly designs and materials for their container packaging to achieve their sustainability goals. Since it has been challenging to decarbonize PET, each company has proactively shifted the primary material used for soft drink containers from traditional virgin PET (vPET) resins to recycled PET (rPET) resins.

There are two ways to make PET bottles more sustainable. One method is to use rPET materials, which are mainly made through bottle-to-bottle recycling. In this process, new PET bottles are made from old ones. Another method is to use plant-based biomass PET materials. Although some companies have started using biomass PET, it has not yet been implemented commercially.

Noteworthy Topics

Japan Had 373,000t per Year of rPET Supply Capacity for Bottle-to-Bottle Recycling as of December 2024

As of December 2023, Japan's supply capacity for rPET resins for bottle-to-bottle recycling was 348,000 tons per year, incorporating both material and chemical recycling methods.

As new recyclers, including recycling companies and recycled resin manufacturers, are scheduled to enter the market between 2024 and 2025, the supply capacity for rPET resins for bottle-to-bottle recycling is expected to increase to 373,000 tons per year by December 2024. This figure is forecast to further rise, reaching 445,000 tons per year by 2025. This includes the output volume from existing recyclers and production facilities under construction, as well as those production facilities that plan to increase their output.

In 2021, the Japan Soft Drink Association, an industry association for soft drinks, set a goal to achieve a 50% recycling rate for PET bottles by 2030. This goal seems achievable given the current supply capacity for rPET.

Future Outlook

The production capacity of rPETs for bottle-to-bottle recycling does not necessarily match the output volume.

Bottle-to-bottle recycling involves more than molding resins from used PET bottles into new ones. It also requires repolymerization facilities and technologies to restore the intrinsic viscosity (IV) of PET resins. The IV is reduced by the heat during molding and recycling processes and needs to be raised to withstand blow molding. Additionally, resins originating from used PET bottles must meet strict safety and hygiene standards for use in beverage containers. Companies, therefore, are required to develop alkaline cleaning techniques to thoroughly eliminate foreign substances and contamination. They must also enable traceability throughout the rPET production processes, including the transportation and storage of materials for each process.

Even if it passes various tests, such as a surrogate test, a dissolution test, and a sensory evaluation, and is guaranteed to function as a resin and approved as a material, a tiny trace of color from a foreign substance can cause a brand owner to reject it as a container material. This makes the rPET highly unlikely to be adopted.

The extent of rPET contamination or discoloration cannot be identified when the material is in pellet form. This can only be discovered when it becomes a preform, just before being blow molded. Therefore, recyclers do not know if their rPET qualifies the appearance standards of a brand owner until they receive feedback.

Recyclers planning to start producing rPET after 2025 will likely need time to stabilize the quality of their products once they begin operating. Therefore, they are not expected to contribute significantly to increase Japan's total production capacity until 2027 or 2028. To produce rPET consistently, newly entered recyclers must conduct technological research and development to improve quality in the medium to long term, while meeting beverage container safety and hygiene standards.

Research Outline

2.Research Object: Eco-friendly material related manufacturers

3.Research Methogology: Face-to-face interviews (including online) by expert researchers, and literature research

What are Eco-Friendly Materials?

Environmentally friendly materials or eco-friendly materials refer to plant-based cellulose nanofibers (CNF), also called nanofibrillated cellulose (NFC), cellulose microfibrils (CMF/CeF), automotive interior and exterior decorative films used as paint substitutes, perovskite solar cells, polyacrylonitrile (PAN)-based carbon fibers used for lighter structures such as airplanes and automobiles, and food/beverage containers (paper cartons, metal cans, lightweight plastic containers) that help reduce the use of plastics.

<Products and Services in the Market>

Recycled PET resins for Bottle to bottle recycling

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.