No.3529

PET Bottle Recycling Market in Japan: Key Research Findings 2023

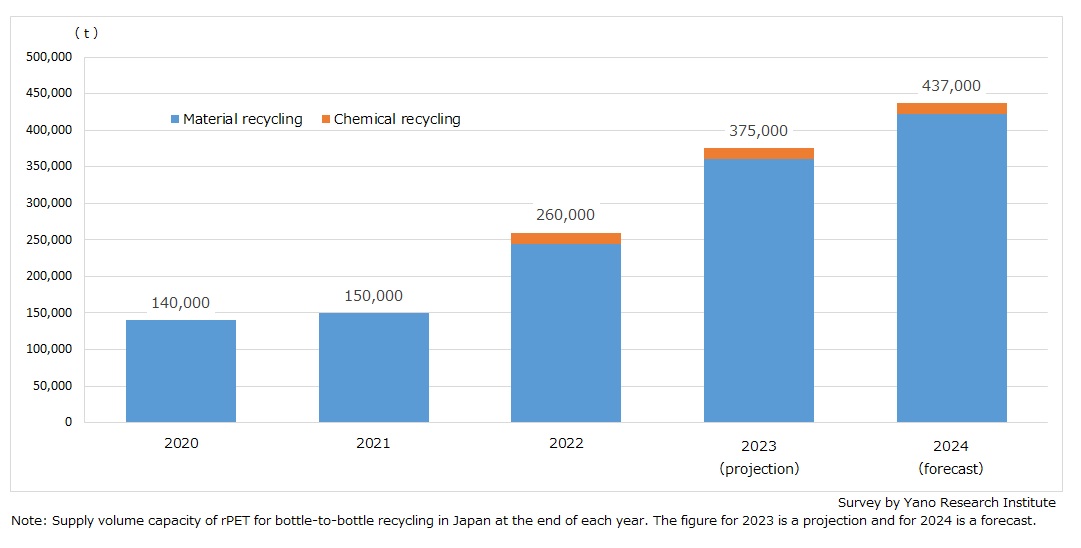

Domestic Annual Supply Volume of Recycled PET Resin for Bottle-to-Bottle Recycling Expected to Reach 437,000t by 2024 Year-End

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the trends of domestic suppliers of environmentally friendly materials, and found out the trends by product segment, the trends of market players, and future perspectives.

This press release denotes the outlook on the domestic supply capacity of recycled PET resin (rPET) for bottle-to-bottle recycling.

Market Overview

Leading brand owners of soft drinks (beverage manufacturers) individually set sustainability goals on packaging, from the standpoint of designing eco-friendly packaging and/or using sustainable materials for the packaging. In particular, decarbonization of PET bottles has been a challenge for the brand owners as PET bottle is a major container used for soft drinks. They have been vigorously embarking on using recycled PET resin (rPET) or biomass PET as alternatives to virgin PET resin (vPET).

There are two approaches to make PET bottles 100% sustainable (to materialize sustainable business): One is a use of recycled materials, as represented by “bottle-to-bottle recycling”, which refers to the use of waste PET bottles as raw materials of new PET bottles, and the other is a use of plant-derived materials (biomass PET resin). However, as biomass PET has not been adopted on commercial basis in most cases, at present, brand owners are making efforts to reach their sustainability goals mainly through bottle-to-bottle recycling.

Noteworthy Topics

Supply Volume of rPET for Domestic Bottle-to-Bottle Recycling for 2023 Expected to More Than Double That of 2021

To reach the volume target of rPET for bottle-to-bottle recycling at brand owners (beverage manufacturers), suppliers need to produce enough amount of rPET to fulfill their demand for PET resin. However, to produce new PET bottles with waste PET bottles as raw materials, suppliers are required not only to produce safety and hygiene assured resins that meet strict quality standards for beverage containers, but also have a polymerization equipment and technology to increase intrinsic viscosity (IV) of resins, so that they are strong enough to be blow molded during fabrication of drink bottles.

Initially, there were limited number of recyclers capable of producing rPET from collected waste PET beverage bottles to be fit for beverage containers. The annual supply volume of rPET for bottle-to-bottle recycling as of December 2021 was 150,000t, which was only one-third of rPET required at beverage manufacturers.

Nonetheless, as the production capacity at existing recyclers increased and new recyclers entered the market to meet a rising demand for bottle-to-bottle recycling, by the year-end of 2022, the annual supply volume increased to 260,000t. Driven by the acceleration of these trends, the annual supply volume of rPET for bottle-to-bottle recycling was estimated to have attained 375,000t in 2023, which is more than twice the volume of 2021.

Since the increase of production capacity at existing recyclers and new market entries are continuing in 2024, if everything goes as planned, the annual supply volume of rPET for bottle-to-bottle recycling is forecasted to expand to 437,000t by the end of 2024.

Future Outlook

While suppliers increase the production capacity of rPET for bottle-to-bottle recycling, how to secure sustainable supply of waste PET bottles as raw materials has increased criticality. The volume of high-quality waste PET bottles collected, i.e., those usable as raw materials for resins for bottle-to-bottle recycling, is less than the volume required at recyclers. The shortage of raw material will be an issue hereafter.

To secure sustainable supply of raw materials to produce rPET for bottle-to-bottle recycling, it is utterly important to utilize waste PET bottles collected by private sectors, such as those collected from recycling bins located next to vending machines, in addition to those municipally collected.

Foreign substances or impurity of waste PET bottles collected by private sectors can be removed through alkali cleaning or polymerization process. Still, the rPET made of these may be slightly tinted, which are often not fulfilling the quality standards at brand owners (beverage manufacturers). For this reason, most of the private-sector-collected waste PET bottles are exported after being pulverized into flakes. If these can be used for domestic recycling, it may ease the supply-demand imbalance of rPET for bottle-to-bottle recycling.

Although the appearance quality of rPET made of privately-collected waste PET bottles may not be as good as virgin PET or recycled resin made of municipally-collected waste PET bottles, as long as the resin meets the quality standards set in “Guideline for safety assurance in the manufacture etc. of food utensils, containers and packaging” by the Ministry of Health, Labour and Welfare, it can be used as raw material for PET bottles as beverage containers. The practice of bottle-to-bottle recycling using rPET made of privately-collected waste PET bottles is already ongoing overseas. Brand owners (in Japan) must decide on their level of commitment to bottle-to-bottle recycling.

In order to achieve 100% bottle-to-bottle recycling by 2030, the question is whether it is appropriate for brand owners to avoid using resins with a 'poor' appearance, even if they are safe. While suppliers will continue to be expected to develop technology to increase appearance quality, it may be time for all stakeholders to reconsider excessive quality criteria.

Research Outline

2.Research Object: Suppliers of environmentally-friendly materials

3.Research Methogology: Face-to-face interviews by our expert researchers (including online interviews) and literature research

What are the Environmentally Friendly Materials?

The environmentally friendly materials in this research indicate cellulose nanofiber derived from plant fibers (CNF), recycled carbon fiber (rCF), and food packages & beverage containers that contributes to reduction of plastic use (paper cartons, paper cups, aluminum cans). Nevertheless, this market report also targets to the trends of recycling on various materials (PET bottles, PET films, light-weight plastic containers, paper cartons, paper cups, aluminum cans, and CFRP).

<Products and Services in the Market>

Recycled PET resin (rPET) for bottle-to-bottle recycling

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.