CNF (Cellulose Nanofiber) Market in Japan: Key Research Findings 2017

Research Outline

- Research period: May to July, 2017

- Research target: Manufacturers of cellulose nanofiber (paper manufacturing companies, chemistry manufacturers, and etc.)

- Research methodologies: Face-to-face interviews by the expert researchers, surveys via telephone/email, and literature research

Summary of Research Findings

- With Commercial Products Using CNF (Cellulose Nanofiber) Being Limited, Most of CNF Produced Supplied as Samples

The domestic research and development of CNF (Cellulose Nanofiber), which had started mainly at universities and R&D institutions in the 1990s, has begun being led by the government since 2014, with the cooperation of industry, government, and schools, aiming to bring it into practical use. However, the commercial products that utilize CNF is limited to those such as ink for ball point pens, paper diapers, wet wipes (paper), headphone diaphragm and etc. Not all of CNF that has been produced is used in merchandises, but rather, most seems to have been supplied as samples.

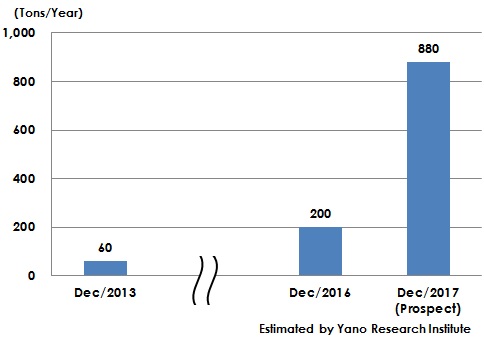

- With Operation of Mass-Production Plants Started, Domestic Production Capacity Projected to Achieve 880 Tons per Year as of End of 2017

In addition to pilot plants at each of manufacturers, operations of mass-production plants aiming for commercial production have finally started during the period between 2016 and 2017, which is likely to make the domestic production capacity of CNF to achieve 880 tons per year as of the end of 2017. This is expected to solve the problems of limited capacity to produce and supply CNF, which had prevented the CNF market from expanding.

- CNF Provides High Functionality When Composited with Resin or Fiber, Making Things Stronger or Lighter in Weight

Except for films and nonwoven fabrics, CNF is rarely used by itself, but used in combination with resins and fibers, by which it contributes to increase crystallinity, strength, flexibility, and dimensional stability, making the products stronger and lighter. Just like carbon fibers and other materials, extensive use and market expansion of CNF can take shape by being synthesized with other materials and not by being used alone. Therefore, one of the challenges of development of CNF is how to easily blend with resins, fibers and solvents.

- Figure 1 :Transition and Forecast of Annual Production Capacity of Domestic

CNF (Cellulose Nanofiber)