No.2268

Transparent Vapor Deposited Film Market for Barrier Films for QD-Sheets: Research Findings 2019

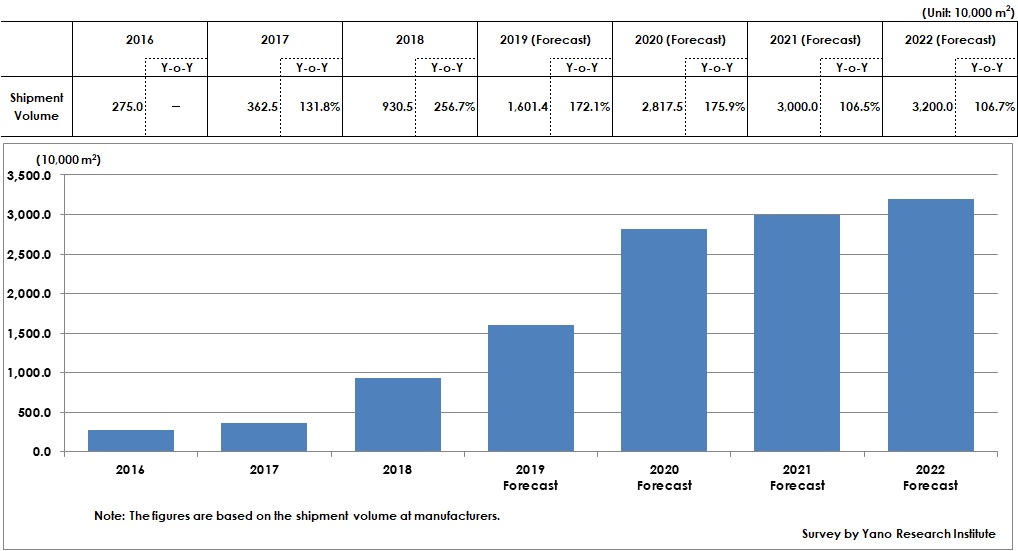

Shipment Volume of Transparent Deposition Films for Barrier Films Used in Quantum Dot Sheets Attained 9,305,000 m2 in 2018

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the domestic and overseas trends of industrial and packaging-use barrier films and has found out the trend by product segment, the trend of market players, and future perspectives. Here describes the transparent vapor deposited film market for barrier films used in quantum dot sheets.

Market Overview

Barrier films aim to protect the object from external environment such as steam (moist) or gas (oxygen, carbon dioxide, etc.) to keep optimal product quality and performance. There are largely two applications for the film, i.e., for packaging and industrial use. Industrial barrier films are mainly used for electronic devices to provide a new value, i.e., “flexibility”, replacing the conventional glass and other “rigid” components. This has created new opportunities for new market exploration.

On the other hand, however, the new market formed has not grown to live up to the expectations yet, with the current largest demand being quantum-dot-sheet barrier films, i.e., a backlight component for quantum dot displays. The market size of transparent vapor deposited films for barrier films used for quantum dot sheets, based on the shipment volume at makers, achieved 9,305 thousand square meters in 2018, showing quite a large volume of barrier films used for quantum dot sheets. However, when observing the market of high-barrier films, using them for electronic paper or organic photovoltaics substrates is still limited at around several ten thousand square meters annually.

Noteworthy Topics

Trend to Introduce Barrier Films

At first when quantum dot displays that use on-surface method were introduced for quantum dot TVs and monitors, the barrier films for quantum dot sheets installed as a backlight component were the substrate films forming barrier layer by way of spattering. Later, vacuum deposition barrier films, which have inferior in barrier performance than the first one, have begun being used, because cost for the component is requested to be reduced, and because the reliability for quantum dot materials have improved.

Vapor deposited films used as barrier films for quantum dot sheets are generally the substrate PET films with transparent vapor deposition layer laminated. In 2016 when such films were introduced at first, two layers of transparent deposited films had been used. Later, improved proportion of resins, and some measures to coat on the surface of quantum dot particles, and aiming for cost reduction, only one layer of transparent vapor deposited film became durable to keep the performance and longevity, without quantum dot being deteriorated. As a result, the makers shifted to one-layer transparent vapor deposited film since 2017. As the demand stably increasing, the market size of transparent vapor deposited films for barrier films in quantum dot sheets is projected to attain 32,000 thousand square meters by 2022, based on the shipment volume at manufacturers.

Future Outlook

In order to expand the demand for industrial barrier films which remains smaller market size than those for packaging, instead of keeping strong preference for flexible displays and replacement of glass, like they used to be, it is indispensable for the makers to recognize what is expected by the user companies and to make clear of the target audience and application from the very beginning. Barrier film makers are required to explore new demand and consider what they can offer to the users in terms of sustainability which various industries recently pay attention to.

As an attempt of developing eco-friendly applications, the development of barrier films for packaging composed of single material is in progress by using the same substrate films as sealant films. As for the films for industrial use, rather than supplying “barrier films”, there are attempts to directly form barrier membrane on the flexible display substrates or on the surface of cover films, aiming to reduce the number of films used.

Besides exploring sustainability demand, another way for the market players to survive may be to accept contract processing from user companies. For instance, by using their own technologies and equipment, barrier film makers may be able to attach barrier properties on to the materials and components that user companies specify. By being contract processers, they may be able to create close relationship extensively with the makers of materials (such as original fabrics, barrier materials, solutions and binders) and of equipment (such as vapor deposition equipment, sputtering systems, and coaters) in order to exchange information and to create cross-maker relationship to ally in the barrier-film business, thereby binding the separate demand into a line of demand with some common aspects, broadening the technological development. As a result, they may be able to generate an unprecedented market that promotes new solutions to their user companies.

Research Outline

2.Research Object: Barrier film makers, converters, makers of ingredients, devices and equipment

3.Research Methogology: Face-to-face interviews by the expert researchers and literature research

What are Barrier Films?

Barrier films aim to protect the object from external environment such as steam (moist) or gas (oxygen, carbon dioxide, etc.) to keep optimal quality and performance. There are following types of barrier films: 1) substrate films coated through drying environment such as vapor disposition, CVD, and spattering, and wet environment (PVA coating); 2) Resins equipped with barrier property such as EVOH and Ny, produced into films; 3) Those made by laminating “barrier” films and “non-barrier” films.

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.