No.2773

Global Market of Polyimide (PI) Films for FCCL (Flexible Copper Clad Laminate): Key Research Findings 2021

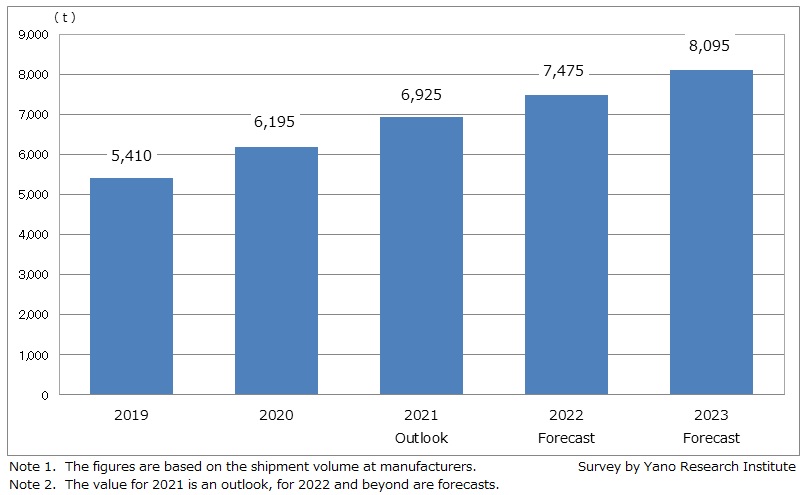

Global Shipment Volume of PI Films for FCCL Expected to Attain 6,925 Tons in 2021

Yano Research Institute (the President, Takashi Mizukoshi) carried out a survey on the global market of high performance films, which includes base films and fabricated films for display panel/optics, electrical/electronics, and other industrial use, and found out the trends by product segment and by market players, and future perspectives.

In this press release, the transition and forecast of the global market of polyimide (PI) films for FCCL and future perspective of low-dielectric film for circuit board are announced.

Market Overview

Global market size of PI (polyimide) films for FCCL (Flexible Copper Clad Laminate) is expected to reach 6,925 tons for 2021, 111.8% of the preceding year (based on the shipment volume at manufacturers).

In 2021, production of smartphones stayed stable between January and March, which is normally the period that experiences cool down in demand after the ‘special demand’ in the end of the year and New Year holidays, such as Christmas and Chinese New Year. It is growing even in April and beyond.

Viewing at the other application of the PI film, the demand expanded for flexible printed circuits (FPC) for in-vehicle sensors and battery controls, driven by the automakers’ use of CASE framework that increased installation of electrical components in vehicles. Moreover, due to the expansion of xEV market, PI films for non-ICT applications such as insulating tapes for in-vehicle Lithium-ion batteries (LiB) expect a double-digit growth.

Noteworthy Topics

Development of Modified PI (MPI) with Low-Dielectric Loss Tangent/Low Moisture Absorption in Progress

Until recently, PI films were often used as insulation films for FPC, TAB, and antennas, owing to their mechanically, electrically and chemically superior characteristics even in ultra-low temperature (-269 degree Celsius) and super-high temperature (400 degree Celsius). While conventional PI films that have the moisture absorption rate above 1% and 0.01 dielectric loss tangents (10 to 28 GHz bandwidth) are sufficient for the 4G, it is not enough for the high speed/high capacity data streaming that 5G (the 5th generation mobile network) requires; slowdown in data transmission speed/capacity due to transmission loss is a matter of concern.

For the stand alone (SA) mode high frequency bands, particularly the sub-6-GHz and millimeter-wave (mm-wave) bands, low-permittivity substrate is required to suppress the transmission loss. PI film makers are developing modified PI (MPI) to lower the moisture absorption rate and dielectric loss tangent.

Moreover, there are some cases where circuit manufacturers start adopting LCP (liquid crystal polymer) instead of PI film as a substrate material for 5G smartphone antennas, because LCP excels especially in low moisture absorption and in electrical properties.

Future Outlook

Presently, deployment of commercial 5G network is limited to the city areas in developed countries only, and most of the 5G-enabled smartphones use a 5G service that does not stand alone, but is built over an existing 4G LTE network (Non Stand Alone; ‘NSA’).

For such 5G-enabled smartphones, the low-dielectric MPI films adaptable to sub-6-GHz and mm-wave bands are too excessive. Some smartphone makers attempt to utilize existing PI films by shortening FPC that connects antenna with circuit board in order to suppress transmission loss. Therefore, in the current situation, it is assumed that the sales of low-permittivity MPI for sub-6-GHz and mm-wave bands make up only a small portion of total sales at manufacturers. The low-dielectric MPI market cannot expect major expansion until standalone 5G networks are fully deployed.

Research Outline

2.Research Object: Manufacturers of high performance films

3.Research Methogology: Face-to-face interviews by the expert researchers (including online interviews) and literature research

What are the High Performance Films?

The high performance films in this research refers to the base films and fabricated films for display panels/optics, electrical/electronics, and other industrial use, including PET film, cover film for foldable phones, low-dielectric film, and MLCC release film.

<Products and Services in the Market>

PET film, MLCC release film, PI film, transparent polyimide film, LCP film, PPS film, polyurethane film, transparent aramid film

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.