No.3797

Biomass Filler Market in Japan: Key Research Findings 2025

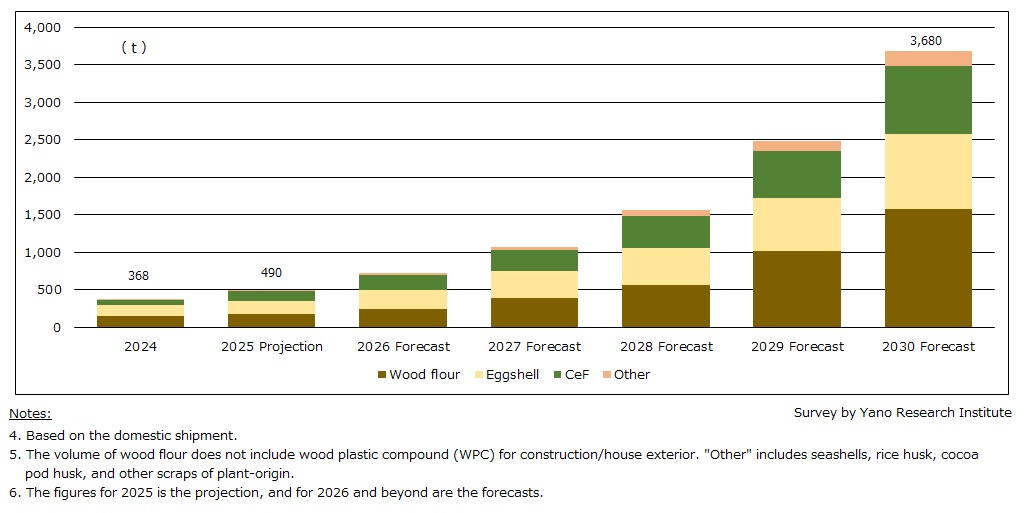

Domestic Annual Production of Biomass Fillers and Biomass Filler Resins Forecasted to Reach 1,605t and 3,680t by 2030 Respectively

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on the domestic market of biomass fillers and biomass filler resins, and found out the trends of market players and future perspectives.

Market Overview

In Japan today, biomass fillers are produced typically from materials such as wood flour, starch, cellulose fiber, seashells, and eggshells. While cellulose fiber and starch are manufactured industrially, many biomass fillers originate from byproducts, so called “remains”: wood scraps from construction sites, offcuts from wood processing facilities, timber from thinning of forests, waste shells of scallop and oysters from seafood processing, and eggshells in egg processing operations.

Traditionally, these byproducts were repurposed for agricultural use, serving as fertilizer, animal feed, or soil conditioners. Seashells and eggshells also found a secondary usage as field marking powder for school sports grounds. However, the volume of these scraps has long exceeded demand in such applications. As a result, biomass fillers were often perceived as low-value, downcycled materials with limited appeal beyond basic reuse.

In recent years, growing concern over environmental issues like climate changes and marine pollution has surged the demand for carbon neutrality, largely driven by efforts to reduce carbon emissions. This has created a strong push to reduce reliance on petroleum-based plastics and transition to renewable materials, moving away from finite resources like petroleum and minerals. In this context, the use of composites containing a high proportion of biomass-based fillers like wood flour, eggshell, and seashell is gaining momentum, particularly in everyday goods, toys, and general merchandise. These materials are no longer viewed merely as downcycled waste; instead, they are seen as upcycled, higher-value products, creating new opportunities for innovation and sustainability in product development.

In the market survey, we targeted the trends of the upcycled biomass fillers. In 2024, the market size of the biomass filler resins is valued at 368t, with upcycled biomass fillers at 189t. In 2025, the volume of biomass filler resins is expected to grow to 490t (133.2% YoY), and the volume of upcycled biomass fillers to 254t (134.4% YoY). By 2030, the volume of biomass filler resins is projected to grow to 3,680t, and the volume of upcycled biomass fillers to 1,605t. (All excluding the volume of wood flour for construction.)

Noteworthy Topics

“Beyond Plastic Alternative” Required For Biomass Fillers Market to Take Additional Leap

In recent years, efforts to reduce plastic usage by incorporating biomass filler resins have expanded across a range of industries. Notably, under current waste separation and recycling regulations in most Japanese municipalities, products containing more than 51% biomass filler by weight are classified as "combustible waste" rather than "plastic waste." This classification simplifies disposal and is likely to drive continued growth in the use of biomass filler resins for everyday goods and general merchandise, which do not presently have recycling system/scheme.

At the same time, while the value of biomass fillers has evolved beyond their traditional role in downcycled materials, their overall market positioning still needs to be elevated.

As long as they are seen merely as substitutes for existing materials, comparison based on cost and properties will remain predominant. Without a clear advantage, product owners may hesitate to adopt them. To move from being an alternative to being a preferred material, biomass filler resin manufacturers must focus on creating unique value propositions that go beyond substitution.

Future Outlook

Biomass filler is not a new material. It has been widely used in applications like wood-plastic composites (WPC) and as a filler in composite resins to reduce plastic content. However, its adoption in categories like fashion, tableware, and other non-traditional plastic applications is still in the early stages of growth.

To expand into new industries, manufacturers of biomass filler resins must move beyond past successes and established uses. This requires a proactive, strategic marketing approach—one that clearly defines target applications and customer segments. It’s essential to identify how biomass fillers can align with or enhance the performance, aesthetic, and sustainability goals of different brands and industries.

The key question is: what exactly resonates with potential customers? Is the bio-based nature of the material a meaningful differentiator? Does the unique texture or design potential offer added value over conventional plastics? Biomass filler resin manufacturers need to grasp the trends in fields they may not have traditionally engaged with, such as fashion, tableware, furniture, and automobiles. Sustainability metrics like CO₂ reduction and reduced plastic use are important but not enough.

Research Outline

2.Research Object: Manufacturers of biomass fillers with cellulose, wood flour, eggshell, and cocoa pod husk, manufacturers of biomass filler composite resins, and related businesses

3.Research Methogology: Face-to-face interviews by our expert researchers (including online interviews) and literature research

What is the Biomass Filler Market?

In this research, biomass fillers refer to fine powder made from biomass-derived raw materials such as cellulose, wood flour, eggshell, cocoa pod husk, vegetable scrap, rice husk, and seashells. However, the target of this market survey is the value-added plastic composites (upcycled), instead of biomass filler itself.

In calculating the market size of biomass filler market, we excluded the market size of wood flour and wood flour composites for construction materials. Given its 30-some years of history, being a common construction material since the 90s, we came to conclude that the trends of upcycling explored in this market survey do not apply to the market trends of wood flour composites.

<Products and Services in the Market>

Biomass fillers and composite resins made from cellulose, wood flour, eggshell, cocoa pod husk, vegetable scrap, rice husk, etc.

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.