Forecast of Global Demand of CFRP for Automobile Manufacturing: Key Research Findings 2016

Research Outline

- Research period: July to October, 2016

- Research target: Manufacturers of automobiles, carbon fiber, fabrication, and machinery, R&D institutions, and other organizations

- Research methodologies: Face-to-face interviews by the specialized researchers, surveys via telephone/e-mail, and literature research

<What is CFRP (Carbon Fiber-Reinforced Plastic)?>

Carbon fiber-reinforced plastic or CFRP is an extremely strong and light fiber-reinforced plastic which contains carbon fibers. Relative density of carbon fiber is quarter of that of iron, but the strength is ten times larger. Carbon fiber is used as CFRP in most cases, and it is only used as it is in a part of seat heaters. Note that CFRTS uses thermosetting resin for its matrix, whereas CFRTP (carbon fiber-reinforced thermoplastic) uses thermoplastics resin. The results of this research include both of the reinforced plastics.

<What is Demand of CFRP for Automobile Manufacturing?>

Demand of CFRP for automobile manufacturing, or automotive CFRP, in this research indicates demand of carbon fiber/CFRP used as a part of structural materials of automobiles such as monocoque-bodies (a car frame and body built as one piece), cross members, pillars, center consoles, and etc., and as replaceable parts such as bonnets, hoods, backdoors, and etc. Note that carbon fiber/CFRP used for hydrogen tanks in FCV (fuel cell vehicles) is not included.

Summary of Research Findings

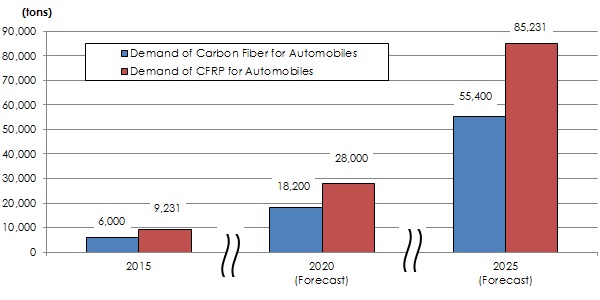

- Global Demand of Automotive CFRP in 2015 Reached 9,231t, Projected to Achieve 28,000t by 2020

Global demand of CFRP (Carbon Fiber-Reinforced Plastic) for automobile manufacturing in 2015 is estimated to attain 9,231 tons. CFRP is expected to start being fully adopted for automobile manufacturing in around 2017. Its adoption in a form of monocoque (a car frame and body built as one piece) is likely to be attained by 2020, mainly in manufacturing of luxury cars, such as BMW i3/i8 models. CFRP is also expected to be adopted mainly in some structural materials of automobiles and also for replaceable parts (such as bonnets, hoods, backdoors, etc.) Such adoption for auto manufacturing is to start mainly from replacement of iron parts to CFRP parts, which is likely to increase the demand of automotive CFRP to attain 28,000 tons by 2020.

- Progress of Automobile Manufacturing to Use Multiple Materials Raises Global Demand of Automotive CFRP to Attain 85,231t by 2025

By 2020 and beyond, CFRP for automobile manufacturing is expected to evolve from mere replacement of iron parts to reviewing of the whole designs of automobile materials, which is expected to bring about automobiles built with hybrid materials (such as iron + CFRP or aluminum + CFRP). Such development is expected to lead to adoption of CFRP not only limited to current luxury cars but also to those lower-priced ones with larger production volume. This may cause adoption of CFRTP (carbon fiber reinforced thermoplastic)-molded articles in automobile manufacturing, which is projected to raise the global demand of automotive CFRP to 85,231 tons by 2025.

- Figure 1: Forecast of Global Demand of Carbon Fiber/CFRP for Automobile Manufacturing