Global Next-Generation Manufacturing Software Market: Key Research Findings 2015

Research Outline

- Research period: From December 2014 to June 2015

- Research targets: Leading vendors providing software for the manufacturing industry

- Research methodologies: Face-to-face interviews with expert researchers, surveys via telephone/email, and literature search

<What is the Next-Generation Manufacturing Software?>

This research considers IoT-utilized software for the manufacturing industry as the next-generation manufacturing software and calculated the global market size. The global next-generation manufacturing software market size is defined as the market size of those systems that the industry have conventionally used for facilitating manufacturing, added with IoT (Internet of Things) platform. Those conventionally-used systems in the manufacturing industry include PLM (Product Lifecycle Management), MOM/MES (Manufacturing Operations Management/Manufacturing Execution System), and SLM (Service Lifecycle Management).

Summary of Research Findings

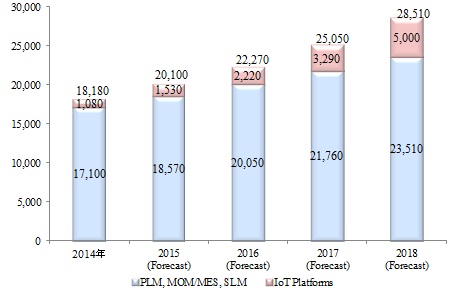

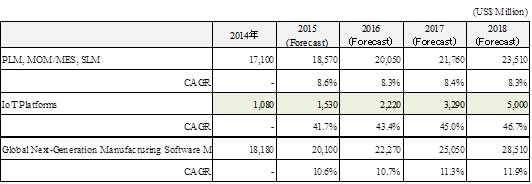

- Global Next-Generation Manufacturing Software Market in 2014 Reaches US$18,180 Million

Utilization of IoT (Internet of Things) in the manufacturing industry has led to the recent new movements, including Industry 4.0 and Industrial Internet. These new movements largely influence software industry, which this research positioned as the next-generation manufacturing software. The global next-generation manufacturing software market in 2014 is projected to attain US$18180 million.

- “Digital Twin” Became New Keyword

In the coming years, the idea of “Digital Twin”, indicating virtual reproduction of existing factories and products, is likely to be essential. In the next-generation manufacturing, IoT technologies allow acquiring, collecting and storing of data of the existing factories and products, connect them with Digital Twin, by which the accuracy of the simulations conducted in computers is to be improved.

- Increasing Importance of Data Linkage

There is no doubt that utilization of IoT platforms steadily increases data volume sent from factories and products. Enterprises should lose no time in constructing a corporate information system that enables overall optimization. Whereas many of the information systems at production sites are separated and disconnected with each other, data linkage between the systems of practical production and engineering is likely to become more important in the future.

- Table 1 & Figure 1: Transition and Forecast of Global Next-Generation Manufacturing Software Market Size