No.2725

Factory Digitization Market in Japan: Key Research Findings 2021

Next-Generation Maintenance and Visualization by IoT Utilization in Progress in Domestic Factories and Plants

Yano Research Institute (the President, Takashi Mizukoshi) carried out a survey on the domestic factory digitization market, and found out IoT utilization in manufacturing, trend of service-based business model for B2B manufacturing, and attempts of smart factories/digital factories, CPS (Cyber Physical Systems)/digital twins. This paper discloses the forecast of factory digitization market size.

Market Overview

Domestic factories and plants for various businesses and industries have started deploying next-generation maintenance and/or visualization systems, especially in the maintenance processes at production facilities/equipment and in production line monitoring, represented by IoT/cloud or AI-used abnormality/defect surveillance, operation monitoring, maintenance, and energy consumption that can all be visualized. IT has begun being utilized also for quality management, appearance inspection, production optimization, and support for workers. Such deployments stem not only from factory-oriented issues and demand such as labor shortage at production sites, improvement in productivity, energy saving, etc., but also from advancement of IT technologies including IoT, cloud, sensor systems, and AI/Analysis solutions, as well as from decreased costs in various hardware and services.

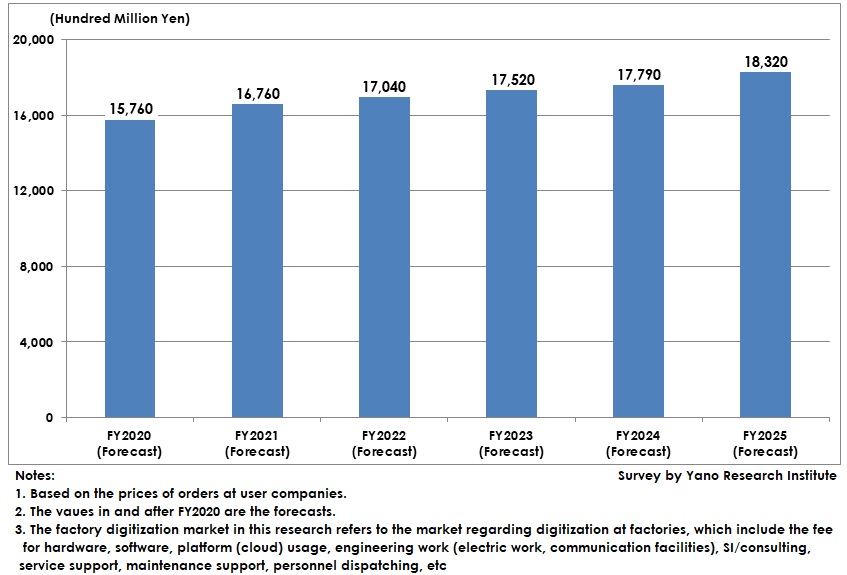

As various digital solutions have been in progress at manufacturing sites, the domestic factory digitization market for FY2020 is expected to reach 1,576.0 billion yen based on the prices of orders at user companies.

Noteworthy Topics

Next-Generation Maintenance and Visualization by Utilizing IoT on the Way at Domestic Factories and Plants

There have been some attempts of minimizing downtime by achieving advanced next-generation maintenance processes such as abnormality/defect detection, predictive maintenance and CBM (condition-based maintenance) that can be performed by uploading the operation data of production facilities and equipment to share them with manufacturers and maintenance service providers. In fact, some IT vendors have already achieved 100 cases of CBM (including those cases at PoC stage), and such vendors have been doubled during the past year.

For instance, a compressor requires high electricity cost which occupies almost 80% of entire expenses for using it (the rest of 20% consists of initial cost, maintenance cost and parts.) Therefore, it is quite apparent that compressors with power saving abilities (electricity cost reduction) have strong appeal. In this respect, availability of “the next-generation visualization” applied to electricity consumption by means of IoT monitoring is largely in demand.

In addition, because those large equipment (boilers, compressors, pumps, etc.) embedded with telecommunication functions (IoT functions) are increasing, IoT utilization has rapidly drawn attention by those user companies planning to newly build factories and production lines, conscious of saving labor and energy, or suffering from serious labor shortage.

Future Outlook

As once suspended projects for FY2020 in the COVID-19 calamity have resumed, and as more factories have shifted to enable remote operations, labor saving, and contactless, the domestic factory digitization market size for FY2021 is expected to rise by 6.3% on a YoY basis to achieve 1,676.0 billion yen, based on the prices of orders at user companies.

Regarding the market toward FY2025, despite the possibility of slowdown in capital investment in some industries, vigorous willingness to invest in digitization for factories at importing machinery manufacturing, electronic products/devices/circuits manufacturing, and machinery manufacturing for production has led the entire market to be stable. In addition, higher demands in some industries for replacement of obsolete production facilities/equipment, and for saving labor and automation at existing factories are also the factors to stabilize the market growth.

Research Outline

2.Research Object: IT vendors, SIers manufacturers of machinery/appliances, user companies and their IT system businesses, and application vendors, etc.

3.Research Methogology: Face-to-face interviews (including online) by expert researchers, surveys via telephone, questionnaire, and literature research

The Factory Digitization Market

The factory digitization market in this research refers to the market regarding digitization at factories, which include the fee for hardware, software, platform (cloud) usage, engineering work (electric work, communication facilities), SI/consulting, service support, maintenance support, personnel dispatching, etc. The market size is based on the prices of orders at user companies. Those appliances procured by user themselves and their in-house digitization attempts are not included.

Reference:

Adoption Rate of Next Generation Monitoring in Factories of Japan: Key Research Findings 2018

https://www.yanoresearch.com/en/press-release/show/press_id/2094?key=gfkd340jdslsopakdk3jdsnmvkd

Failure Prediction in Japan: Key Research Findings 2017

https://www.yanoresearch.com/en/press-release/show/press_id/1725?key=gfkd340jdslsopakdk3jdsnmvkd

<Products and Services in the Market>

Remote surveillance, monitoring system, IoT system (data collection), cloud/IoT platform, image/camera solution, AR/VR solution, ledger solutions, CPS (Cyber Physical Systems)/digital twins, etc.

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.