No.3231

Factory Digitalization Market in Japan: Key Research Findings 2023

Advanced Facility Maintenance via IoT and Deployment of Next-Generation Maintenance in Progress in Manufacturing Industry in Japan

Yano Research Institute (the President, Takashi Mizukoshi) has carried out a survey on the domestic factory digitalization market, and found out the trend in IoT utilization at manufacturing sites, trend of transforming the manufacturing business models from product-centric to service-centric, the efforts to achieve a smart factory or a digital factory, and to use CPS (Cyber-Physical Systems) and digital twins, etc. This paper discloses the factory digitalization market size forecast.

Market Overview

At factories for many industries and business forms in Japan, the deployment of next-generation maintenance systems has started being underway for maintenance and monitoring of manufacturing line operations at production facilities and equipment, through data collection by means of IoT, cloud or AI technologies, which achieves anomaly detection and error monitoring, operation monitoring/remote surveillance, advanced facility maintenance, visualization for energy saving and of observing energy consumption. In addition, IoT has expanded to appearance inspection for checking the products and for quality assurance, advanced automation and production optimization, work support for onsite workers, and training.

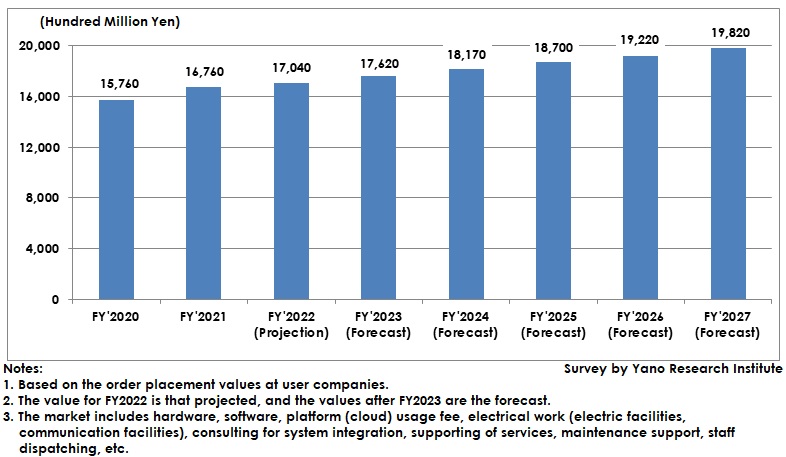

The backdrop against this is that large-scale manufacturing apparatuses, production machinery, and other expensive equipment in recent years are already embedded with communication functions (IoT functions), encouraging the use of IoT at user companies for operation monitoring and remote surveillance of manufacturing equipment, production machinery, and utility facilities (electric facilities, HVAC, and plumbing systems), regardless of the industry, business form or corporate size. Such use of various digital tools at manufacturing sites has led the domestic factory digitalization market for FY2022 to reach 1,704,000 million yen, 101.7% of the size of the previous fiscal year, based on order placement values at user companies.

Noteworthy Topics

Trends of CPS (Cyber Physical System) and Digital Twin

What attract attention in factory digitalization hereafter are CPS (Cyber Physical system) and digital twin technologies because of their high affinity with manufacturing or craftsmanship. Spread of IoT has collected various data and has accumulated them on cloud, which propels a CPS and a digital twin to work.

Currently, many measuring instruments, a variety of sensors, and FA cameras have been installed at a manufacturing line to collect data. By making such data accumulated on cloud, realization of CPS and digital twins is more at hand. Use of CPS and digital twin technologies enables monitoring of a physical space and simulation of a virtual or digital (cyber) space that bases on the data collected and accumulated and that accurately reflects a physical space. These allow anticipation of potential damages and changes in the future, or provision of maintenance services different from regular ones, in that they are based both on experience and things, where customers are able to see the feedback on the measures to solve the cause of abnormality based on the analytic results.

When CPS begins to work, development and improvement of products can be done through marriage between physical and digital spaces, streamlining the work processes and shorting the development period. In addition, as the accumulated data can be the source of competitive edge for a client company, it can improve competitiveness of the client. Furthermore, by providing feedback on usability to a product designer, the product manufacturing processes become more efficient at lower cost. From this on, increasing numbers of manufacturing companies are likely to convert their business models from those that earn profits only by product sales to those that obtain compensation from providing services to client companies by the use of CPS and digital twins.

Future Outlook

In addition to “the initiative of making Japan to take the lead in semiconductor manufacturing” having become the national policy, encouraging companies to plan out their policies to construct new factories and augment semiconductor production capacity, rapid weakening of yen, economic security, and “revival of Japanese manufacturing” in response to measures against the risks of business development in China are fueling the factory digitalization market. According to “Short-term Economic Survey of Principal Enterprise in Japan” the domestic capital investment is expected to be robust, which seems centered on manufacturing equipment and production machinery, but is also likely to increase the spending on IT and IoT geared to factories. The factory digitalization market for FY2023 is projected to generate 1,762,000 million yen, 103.4% of the size of the previous fiscal year.

Research Outline

2.Research Object: IT vendors, system integrators, manufacturers of equipment and appliances, telecommunications careers, user companies and related IT subsidiaries, application vendors, etc.

3.Research Methogology: Face-to-face interviews (including online) by expert researchers, survey via telephone and questionnaire, and literature research

The Factory Digitalization Market

The factory digitalization market in this research targets hardware, software, platform (cloud) usage fee, electrical work (electric facilities, communication facilities), consulting for system integration, supporting of services, maintenance support, staff dispatching, etc., with the market size calculated based on the order placement values at user companies. In other words, the values can be said as cash outflows at user companies, that enable to contrast with the sales at IT vendors, system integrators, manufacturers of equipment and appliances, telecommunications careers, and IT sales at related IT subsidiaries.

Note that those equipment and appliances that user companies themselves have procured for organizing their in-house systems are not included.

<Products and Services in the Market>

Remote surveillance: monitoring system; data collection: IoT systems; cloud: IoT platform; image-related: camera solutions; analysis: AI, AR/VR solutions; ledger solutions, CPS (Cyber-Physical Systems), digital twins, etc.

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.