No.2320

Global 3D Printing Materials Market: Key Research Findings 2019

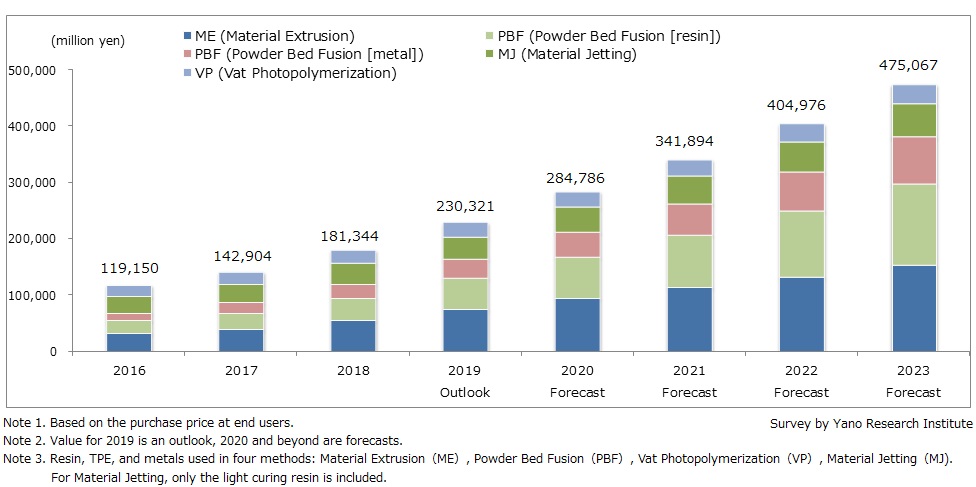

Global Market of 3D Printing Materials Attained 181,344 Million Yen in 2018, Up 26.9% from the Previous Year

Yano Research Institute (the President, Takashi Mizukoshi) conducted a survey on the global 3D printing materials market, and found out the trends by printing method, the trend by market players, and the future perspectives.

Market Overview

The global 3D printer materials market in 2018 is estimated to have generated 181,344 million yen, 126.9% of the previous year. The 3D printing materials market have significantly grown especially at overseas due to the following factors: (1)progress in technological innovation in modeling process (production speed, sturdiness, etc.), (2)diversification and high functionalities of 3D printing materials, and (3)expansion in the application of created objects from prototypes to final products.

Noteworthy Topics

Progress in Technological Innovation of Production Method

After 2015, companies developing new modeling methods that enable faster production of sturdy objects are entering the market, one after another.

For the 3D printing methods using resin materials, many manufacturers are based in the United States, such as HP, which utilizes technology/know-how/intellectual properties accumulated in the 2D printer business, as well as Markforged, Carbon, and Formlabs.

On the other hand, in the 3D printing methods using metallic materials, broader range of technology is available, such as Powder Bed Fusion (PBF), Material Extrusion (ME), and Binder Jetting (BJ). Companies like Desktop Metal, HP, GE Additive, and Stratasys have planned foray into 3D printing market with the Binder Jetting technology.

Future Outlook

Global 3D printing materials market is forecasted to reach 475,067 million yen by 2023 (based on the end user purchase price), with a CAGR of 21.2% during 2018 to 2023.

Looking at the trends for each production method, as to the materials for Material Extrusion (ME), expansion in a range of applications and increase of end users are expected by the evolution in the devices and materials, and the filaments (string-like material) market is presumed to continue rapid growth.

For the material market for Powder Bed Fusion (PBF), demand in the final products is estimated to increase as the companies have developed diversities of resin powder in the open platforms they established for material development.

Meanwhile, as the competition in the 3D printing methods may become severe depending on the direction of device makers, the growth rate of the metal powder market for PBF devices is forecasted to level off after 2020.

As to the materials market for the Vat Photopolymerization (VP), prevalence of the low-end devices and establishment of the common development platform hosted by the dedicated material makers are expected to trigger enhancement in prototyping application and creation of new applications as the final products.

For the materials market of Material Jetting (MJ), while the method competes with ME method using filaments for production tools application, demand for design models in full-color remain stable. Further, final products as the injection molds and medical models are assumed to underpin the demand.

Technological innovation in the 3D printing processes, together with diversification and high-functionalities of materials, is increasing the application of created objects by 3D printers as final products; status of the 3D printer at manufacturers is getting closer to the traditional machine tools. However, it’s less likely to replace the conventional manufacturing machine: Rather, the 3D printer brings benefits by far in the production of prototypes and production tools, or in the low-volume production of diversified products and customized products.

For such reason, continuous development of a new application in the niche market will be required- an application different from objects like mass-produced parts for the automobiles (common cars).

Research Outline

2.Research Object: Companies related to 3D printing (device makers, material makers) etc.

3.Research Methogology: Face-to-face interviews by the expert researchers, and literature research.

3D Printing Materials Market

Various materials are developed and used practically for each printing methods of 3D printers. Main materials are such as resin, thermoplastic elastomers (TPE), metals, ceramics, wax, and gypsum. In addition, as auxiliary material, additives like binder for binder jetting (BJ), reinforcing agents, conductive agents, and colorants are used.

In this research, the 3D printing materials market size includes resin, TPE, and metals used in the four kinds of 3D printing, namely, material extrusion (MEX), powder bed fusion (PBF), vat photopolymerization (VPP), and material jetting (MJT). However, for material jetting, only light curing resins are included.

<Products and Services in the Market>

Resin, thermoplastic elastomers (TPE), metals

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.