No.2123

Metal Injection Molding (MIM) Market in Japan: Key Research Findings 2019

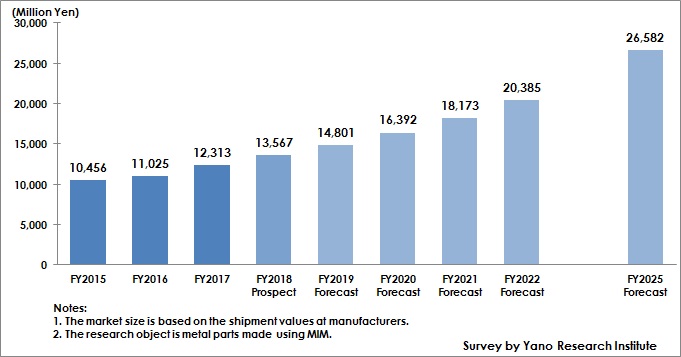

With CAGR of MIM Market from FY2015 to FY2025 Estimated as 9.78%, Market Size Likely to Attain 26,582 Million Yen by Fy2025

Yano Research Institute (the President, Takashi Mizukoshi) has conducted a survey on metal injection molding and has found out the transition and forecast of the market size, the trends of related businesses, and the future perspectives.

Market Overview

MIM or metal injection molding is said to be first developed by Dr. Raymond E. Wiech Jr, the former researcher at NASA, in 1960. MIM is a metalworking process that combines the technologies of resin molding and powder metallurgy to process finely powdered metals. In recent years, it has newly attracted attention as one of those manufacturing methods different from the conventional methods such as forging, casting, or mechanical working.

The market players are not only the MIM specialized makers but also those makers whose main business are die casting, resin molding, and lost-wax casting. The market generally indicates complicatedly-shaped small metal parts. The domestic market has been launched in the late 1980s. At the beginning, the applications of the domestic parts used to be limited to watchbands, sewing machines, equipment for office automation and business machines. However, in recent years, they have begun adopted in various industries such as medical equipment, automobile parts, telecommunication devices, and robots. Such broad acceptance indicates how the technologies at the domestic market players have been responsive to the needs, which is one of the characteristics compared with the overseas makers.

The domestic MIM market for FY2017 is likely to attain 12,313 million yen, based on the shipment values at makers. The market is expected to rise to 13,567 million yen by FY2018, 110.2% of the size of the previous fiscal year. In the status where competition with other metal processing method is fierce, metal injection molding has been recognized as effective, but cost reduction has always been the challenge for the method. In addition, some technological challenges such as optimization of manufacturing processes and dimensional accuracy has been left to be improved. Nevertheless, each maker has promoted the method to raise the awareness at the designing and development departments of user companies which is the doorway to the Japanese “Monodzukuri”.

Noteworthy Topics

Currently, the sales plans by MIM-related makers have been quite clear, where many aiming to achieve 10 to 15% rise from the previous fiscal year. Therefore, most makers have hammered out investment plans to expand their business.

Such investment plans apt to include sintering furnaces and other related facilities and measuring apparatuses, not to mention injection molding machines, i.e., the main manufacturing equipment, together with automation and laborsaving. In some cases, obvious growth paths have been planned with the investment of some hundreds millions of yens transferred to other related business, after having finished providing facilities and equipment to a certain level.

Research Outline

2.Research Object: MIM (metal injection molding) makers, JPMA (Japan Powder Metallurgy Association)

3.Research Methogology: Face-to-face interviews by the specialized researchers and literature research

the MIM (Metal Injection Molding) Market

MIM or metal injection molding is a metalworking process that combines the technologies of resin molding and powder metallurgy to process finely powdered metals. The market size in this research is the shipment values of metal parts manufactured by MIM at manufactures.

Published Report

Contact Us

The copyright and all other rights pertaining to this report belong to Yano Research Institute.

Please contact our PR team when quoting the report contents for the purpose other than media coverage.

Depending on the purpose of using our report, we may ask you to present your sentences for confirmation beforehand.